IntroductionYou grab a bottle of water from the shelf, twist it in your hand, and notice a small tri...

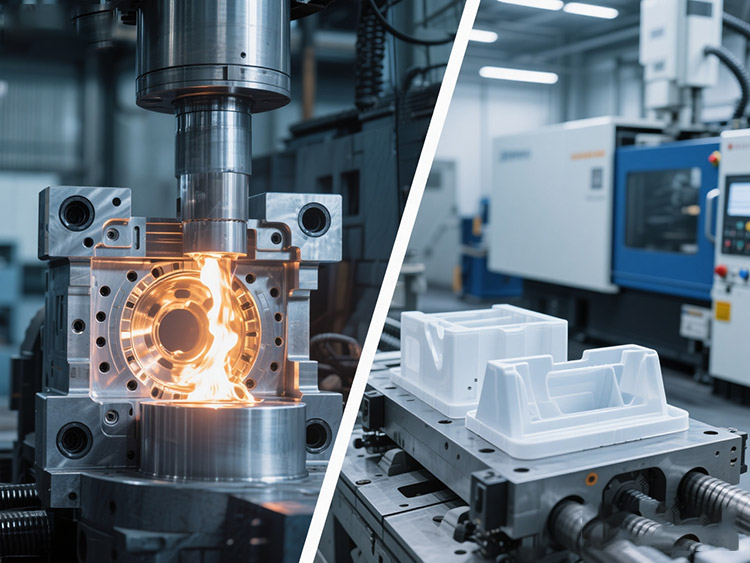

Die Casting vs Injection Molding: How to Choose the Right Molding Process for Your Product

When selecting a manufacturing route, the decision often comes down to Die Casting vs Injection Molding. Both are high-volume, repeatable processes, but they serve different materials, mechanical needs, and cost structures. This guide explains what each process is, walks through step-by-step workflows, highlights advantages and drawbacks, compares key technical metrics (materials, melting point, pressure, cooling time, tolerance, tooling cost), and gives a practical decision matrix so you can pick the right process for your part.

What Is Die Casting?

Die casting is a high-pressure metal casting process where molten metal (commonly aluminum, zinc, or magnesium alloys) is injected into steel molds (dies). The metal solidifies quickly, producing precise, repeatable metal parts used for housings, structural components, and thermal or EMI-sensitive parts.

Step-by-Step Die Casting Process

Design & toolmaking: Hardened steel dies are CNC machined with cooling channels and venting.

Melting: Metal alloys are melted in a furnace to the target temperature.

Injection (shot): Molten metal is forced into the die at high pressure and high speed.

Solidification & hold: The shot is held under pressure to reduce shrinkage while the metal cools.

Ejection & trimming: Die opens, part is ejected and trimmed from gates/runners.

Secondary operations: Heat treatment, machining, surface finishing (anodizing, painting, plating), and inspection.

Pros and Cons of Die Casting

Pros

Excellent mechanical strength and thermal conductivity vs plastics.

Tight dimensional stability for many metal parts.

High production speed — good for large runs.

Attractive surface finish; amenable to secondary finishing.

Cons

High upfront tooling cost and lead time.

Limited to low-to-medium melting point alloys (not for steel).

Potential casting defects (porosity, cold shuts) if process not optimized.

What Is Injection Molding?

Injection molding melts plastic resin and injects it into a mold cavity where it cools and solidifies. It’s the dominant method for producing high volumes of complex plastic parts — from consumer electronics to automotive interiors and medical components.

Step-by-Step Injection Molding

Tool design & build: Steel or aluminum molds are made with runners, gates, and cooling channels.

Material preparation: Plastic pellets (ABS, PP, PA, PC, etc.) are dried and fed to the barrel.

Melt & injection: A screw melts and injects the polymer into the cavity under pressure.

Packing & cooling: Pressure is held to pack material while the part cools.

Ejection & finishing: Mold opens, ejector pins remove the part; trimming and post-processing follow.

Quality control: Dimensional checks, functional tests, visual inspection.

Pros and Cons of Injection Molding

Pros

Wide material choices with tailored properties (flexibility, flame retardancy, chemical resistance).

Excellent surface customization (textures, colors, overmolding).

Extremely cost-effective per piece at high volumes — multi-cavity molds boost throughput.

Easier prototyping options (soft tool, 3D printed inserts).

Cons

Tooling cost can still be significant for complex molds.

Plastics have lower stiffness and thermal conductivity compared to metals.

Warpage, sink marks, and surface defects need careful process control.

Key Differences: Die Casting vs Injection Molding

| Metric | Die Casting | Injection Molding |

| Materials | Metal alloys (Al, Zn, Mg) | Thermoplastics & thermosets (ABS, PP, PA, PC…) |

| Melting/Processing Temp | High (e.g., Al ~660°C) | Low (100–350°C, depending on polymer) |

| Typical Process | Melt metal → high-pressure injection → rapid solidify | Melt polymer → inject under pressure → cool & solidify |

| Injection/Shot Pressure | Very high (tens to hundreds MPa) | High, but generally lower than metal casting |

| Cooling Time | Short (metal cools fast) | Longer (plastic is a thermal insulator) |

| Dimensional Tolerance | Good (depends on alloy & part size) | Excellent repeatability for small features |

| Tooling Cost | Very high (robust, heat-resistant steel) | High (varies by cavity count & complexity) |

| Best For | Structural metal parts, heatsinks, EMI shielding | Complex shapes, color/texture, lightweight parts |

Which Process Is Best for You?

Use this checklist to decide between die casting vs injection molding:

Need metal properties (strength, thermal conductivity, EMI)? → Die casting.

Need lightweight, color, or decorative surfaces? → Injection molding.

Batch size & time to market: If rapid prototyping or small series, injection molding (or prototyping plastics) is usually faster and cheaper to iterate. For large, long production lives with high per-part value, die casting can be ideal.

Tolerance & surface finish: Both can meet tight specs — injection molding often wins for very fine textured surfaces; die casting wins when metal properties are required.

If your projects lean toward injection molding, Topower can help turn that choice into dependable production. Our hot runner temperature controllers — including the modular TP series and the intelligent HY20 touch-screen controllers — support multi-zone, high-cavity molds and are built for precise, energy-efficient temperature control. We also offer time-sequential controllers and a full range of hot-runner accessories to simplify integration with major systems and speed up your time-to-market. For a quick feasibility check, custom configuration, or a quote, contact Topower’s team via their website or email — they’ll help match the right hot-runner solution to your part, cavity count, and production goals.

FAQ

Can injection molded parts be as strong as die cast metal parts?

Plastics can be reinforced (glass fiber, fillers) to approach some mechanical properties, but they typically cannot match metals for stiffness, heat dissipation, or electrical conductivity.

Which has lower lead time — die casting or injection molding?

Injection molding tooling can sometimes be faster for low-complexity molds; die casting molds take longer due to the need for hardened steel and more robust cooling/venting.

Is one process cheaper per part?

Per-part cost depends on material, cycle time, and volume. Injection molding often yields lower per-part cost for simple plastic parts at high volumes; die casting can be cost-effective for metal parts when volumes and part value justify tooling.