IntroductionIn modern injection molding, precision is fundamental. At the center of that precision l...

What Are The Types Of Injection Molding?

Injection molding types determine the right manufacturing path for a product — from standard injection molding for high-volume plastic housings to specialized micro injection molding for medical components. Understanding the main types of injection molding helps engineers choose processes that balance cost, performance and aesthetics. This guide explains each injection molding type, its advantages, trade-offs and practical design tips so you can pick the most appropriate injection molding process for your part.

Standard Injection Molding

Standard injection molding is the foundational plastic manufacturing process in which molten thermoplastic or thermoset material is injected into a closed mold cavity under pressure, then cooled and ejected as finished parts. It is ideal for high-volume production, repeatable tolerances, and complex geometries.

Materials

Common materials include ABS, PP, PE, PC, Nylon (PA), POM, and engineering thermoplastics. Thermoset resins and blends are used in specialized applications.

Typical Applications

Consumer electronics housings, automotive interior components, household appliances, medical device housings (with proper material selection), packaging caps, and connectors.

Advantages

Highly repeatable and scalable for mass production.

Capable of complex geometries and thin-wall parts.

Fast cycle times with optimized molds and cooling.

Wide material selection and property customization.

Disadvantages

High upfront mold cost and lead time.

Long development cycle for tooling and process validation.

Potential defects like sink marks, warpage, short shots, and flash.

Design & Process Tips

Keep wall thickness uniform; add ribs to strengthen thin sections.

Optimize gate location and runner design to reduce weld lines.

Ensure proper venting and cooling channel layout for cycle time.

Use simulation early in design stage.

Overmolding & Two-Shot Molding

Overmolding is the process of molding one material over another — typically a soft elastomer over a rigid substrate — to provide ergonomic grip, sealing, or aesthetic finishes. It may be performed as sequential injection steps using the same mold or via assembly of pre-molded inserts.

Materials

Rigid substrates: PC, ABS, Nylon, POM. Overmold: TPE, TPU, LSR (when compatible), and thermoplastic elastomers.

Typical Applications

Tool handles, toothbrush grips, automotive interior buttons, medical instrument grips, and sealed housings.

Advantages

Improved ergonomics and grip.

Integrated seals and tactile features.

Reduces secondary assembly and adhesives.

Disadvantages

Requires material compatibility or adhesion promoters.

More complex molds and cycle synchronization.

Potential for delamination if adhesion fails.

Design & Process Tips

Design mechanical locking features for weak adhesion scenarios.

Use proper surface treatment or primers to improve bonding.

Control shrinkage differences and tolerance stack-up between layers.

Insert Molding

Insert molding places pre-made inserts (metal nuts, threaded bushings, electronic contacts) into the mold so plastic is injected around them, forming a single integrated part.

Materials

Thermoplastics for the molding stage and metallic inserts like brass, steel, or plated fasteners.

Typical Applications

Plastic housings with metal threads, electrical connectors, sensor housings, and structural mounting points.

Advantages

Eliminates secondary assembly and threaded inserts installation.

Provides durable, high-strength fastening points.

Improves accuracy and repeatability of insert position.

Disadvantages

Inserts must withstand injection temperature and clamp forces.

Mold complexity increases (insert handling/placement required). Automated insert placement systems add CAPEX.

Design & Process Tips

Add physical retention features around the insert (undercuts, knurls).

Consider thermal expansion mismatch; avoid thin plastic around heated inserts.

Ensure clean inserts (no oil) for good bonding.

Gas-Assisted Injection Molding

Gas-assisted molding injects an inert gas (often nitrogen) into the molten plastic inside the mold to create hollow sections or channels. This technique reduces material usage and improves dimensional stability for thick or long flow paths.

Materials

Common thermoplastics like PP, PA, and ABS with adequate melt strength.

Typical Applications

Large handles, housings, thick-walled structural parts, and parts benefiting from hollow cores.

Advantages

Lower material usage and weight.

Reduced sink marks and internal stress.

Improved dimensional control and faster cooling in some cases.

Disadvantages

Requires specialized gas injection equipment and controls.

Not suitable for very thin-walled parts or certain geometries.

Possible surface blemishes where gas breaks through.

Design & Process Tips

Plan gas injection pins and vents carefully.

Ensure melt-front skin is thick enough to avoid gas blow-through.

Use simulation tools to predict gas path and foam core.

Co-Injection (Multi-Layer)

Co-injection molding, also known as sandwich molding, uses multiple materials to form multi-layered parts. Typically, a high-quality resin forms the outer shell while recycled or less expensive resin forms the core.

Advantages

Reduces material costs.

Enhances part performance (e.g., barrier properties).

Enables recycling of lower-grade plastics.

Drawbacks

Complex machinery and tooling required.

Limited to specific material combinations.

Applications

Food packaging.

Automotive components requiring barrier layers.

Industrial containers.

Micro Injection Molding

Micro injection molding produces extremely small, high-precision parts (often less than 1 gram). It is widely used in industries demanding miniaturization.

Advantages

High precision with tight tolerances.

Enables production of complex micro geometries.

Reduces material waste.

Drawbacks

Requires specialized micro-molding machines.

Tooling costs are higher.

Process is sensitive to temperature fluctuations.

Applications

Medical implants.

Electronic micro-components.

Microfluidic devices.

Powder Injection Molding (MIM / CIM)

Powder injection molding combines fine metal or ceramic powders with a binder to create feedstock, which is injected like plastic. After molding, parts undergo debinding and sintering.

Advantages

Allows complex geometries in metal and ceramic parts.

Cost-effective compared to machining for small parts.

Produces high-strength, dense components.

Drawbacks

Requires multiple post-processing steps.

Limited to smaller parts.

High equipment and material costs.

Applications

Aerospace components.

Orthopedic implants.

Precision gears.

Two-Shot (2K) Injection Molding

Two-shot molding injects two materials in one mold cycle to form a single part. It differs from overmolding by completing both steps in one process.

Advantages

Stronger inter-material bonding.

Shorter production times than overmolding.

Creates complex parts with multiple colors or textures.

Drawbacks

Very high tooling and machine costs.

Limited to compatible materials.

Applications

Automotive interior switches.

Dual-color buttons.

Medical instruments.

Reaction Injection Molding (RIM)

RIM uses liquid reactive resins (such as polyurethanes) that cure chemically inside the mold. The process operates at lower pressures compared to thermoplastic molding.

Advantages

Produces lightweight, durable parts.

Excellent for large components.

Supports foamed cores and reinforced parts.

Drawbacks

Limited to thermosetting resins.

Slower cycle times than thermoplastics.

Tooling can wear faster due to chemical reactions.

Applications

Automotive bumpers.

Industrial enclosures.

Medical equipment housings.

LSR Injection Molding

Liquid Silicone Rubber (LSR) injection molding produces flexible, biocompatible components. It uses a cold runner system with heated molds.

Advantages

Excellent heat and chemical resistance.

Biocompatible and safe for medical applications.

High durability with flexible properties.

Drawbacks

Tooling costs are high.

Requires specialized injection molding machines.

Applications

Medical tubing and implants.

Baby products (nipples, pacifiers).

Seals and gaskets.

Structural Foam & MuCell

Structural foam molding introduces blowing agents into the resin, creating foamed, lightweight structures. MuCell® microcellular foaming refines this by creating microscopic bubbles within the part.

Advantages

Reduces part weight.

Improves stiffness-to-weight ratio.

Saves material costs.

Drawbacks

Surface finish can be rougher.

Limited to non-aesthetic parts unless secondary finishing is applied.

Applications

Pallets, crates, and cases.

Automotive panels.

Large industrial housings.

MuCell / Microcellular Injection Molding

MuCell® is a patented form of microcellular injection molding, where supercritical fluids are injected into the resin to form uniform micro-bubbles.

Advantages

Dramatically reduces part weight.

Faster cycle times.

Eliminates sink marks and warpage.

Drawbacks

Requires licensing and specialized equipment.

Limited surface finish options.

Applications

Automotive dashboards.

Laptop casings.

Packaging trays.

Injection Compression Molding (ICM)

In ICM, molten resin is injected into a partially open mold, which then closes to compress the material. This reduces stress and ensures even distribution.

Advantages

Produces thin-walled, high-precision parts.

Reduced residual stress.

Excellent for optical clarity.

Drawbacks

Tooling complexity is higher.

Not suited for all geometries.

Applications

Lenses and optical discs.

Thin packaging.

Transparent covers.

Optical & Cleanroom Injection Molding

Optical molding ensures clarity and precision, while cleanroom molding ensures sterility for medical and electronic components. Both demand specialized environments.

Advantages

High optical clarity.

Contamination-free production.

Tight tolerance control.

Drawbacks

Expensive facilities and operation.

Specialized markets only.

Applications

Fiber optics and lenses.

Syringes and surgical tools.

Semiconductor components.

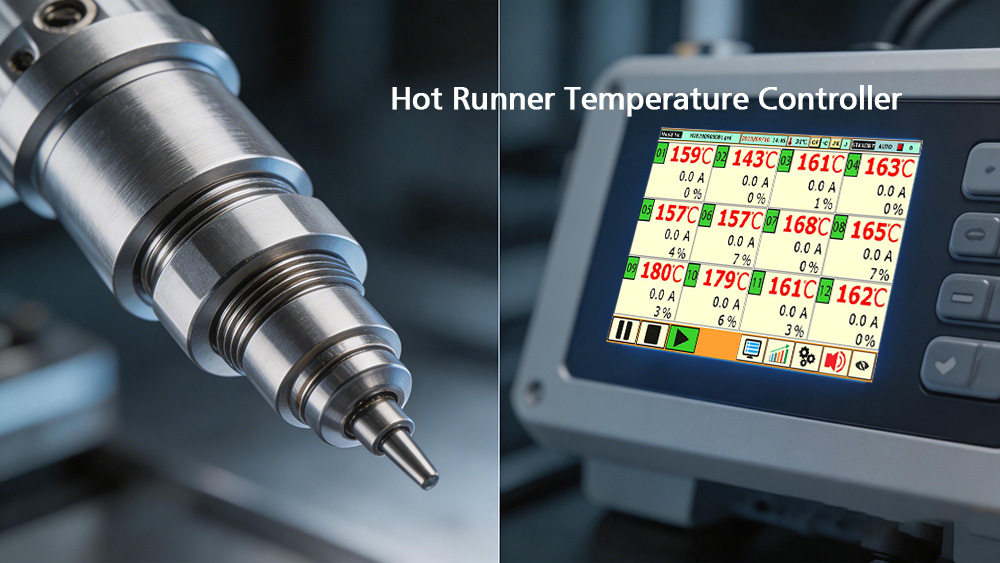

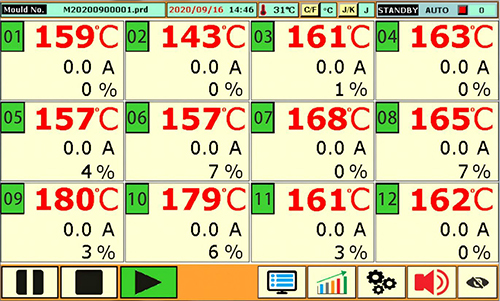

Hot Runner vs Cold Runner — Runner System Comparison

The runner system is critical in injection molding. Cold runners generate more waste, while hot runners keep resin molten within heated channels, delivering it directly into the cavity.

Advantages of Hot Runners

Faster cycles.

Less material waste.

Superior part quality and finish.

Drawbacks

Higher installation cost.

Requires skilled maintenance.

CNTOPower Relevance

CNTOPower’s state-of-the-art hot runner temperature controllers help manufacturers achieve consistent quality, reduced cycle times, and lower production costs — no matter which injection molding type they use.

Conclusion — Choosing the Right Injection Molding Type

Every injection molding type offers unique strengths. From lightweight hollow structures to precision optical parts, the right process depends on application, design complexity, and performance requirements. By integrating hot runner temperature controllers, manufacturers gain improved part quality, sustainability, and profitability.

Looking to optimize your injection molding operations? Contact CNTOPower today to explore our advanced hot runner solutions tailored to your needs.