IntroductionYou grab a bottle of water from the shelf, twist it in your hand, and notice a small tri...

History of Hot Runner Temperature Controllers

Introduction

The hot runner temperature controller is an essential component in modern injection molding systems. It ensures accurate and stable temperature control for the hot runner system, which directly influences product quality, molding efficiency, and energy consumption.

This article explores what a hot runner temperature controller is, its applications, key features, and how it has evolved through decades of technological progress.

What Is a Hot Runner Temperature Controller?

A hot runner temperature controller is a specialized electrical device designed to continuously maintain the target temperature required by a hot-runner system in injection molding.

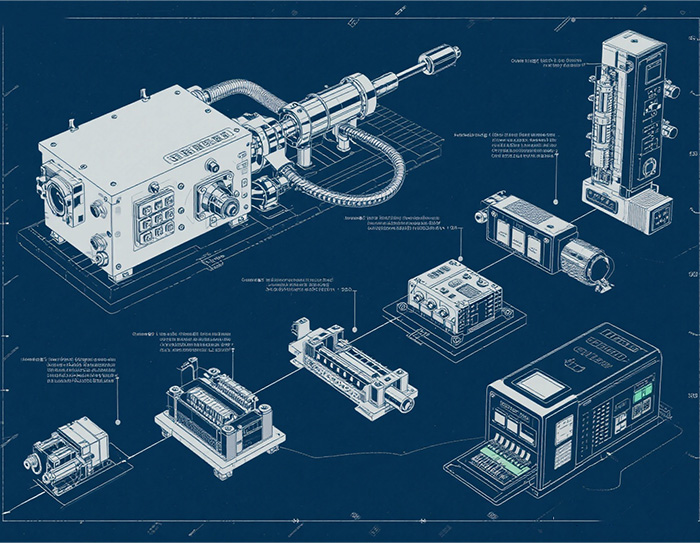

It consists of modules such as a temperature-control card (or cards), circuit breakers, housing (box), fan, terminal blocks, and cables.

How it works:

The controller reads the signal from a thermocouple (typically type K or type J) installed in the hot-runner manifold or nozzle.

A microprocessor-based control card processes the thermocouple signal and uses algorithms (e.g., PID control) to regulate the power supplied to the heater circuits in the hot-runner system, thereby maintaining the melt-path at the set temperature with high precision. (Modern controllers claim control accuracy in the range of ±0.5 °C)

Many controllers provide multi-zone capability, allowing each manifold/nozzle zone to be individually controlled and monitored.

The output interface is standardized (industrial sockets or plug-in modules), enabling modular replacement and ease of servicing.

Controllers often include diagnostics: sensors for thermocouple disconnection or reverse wiring, fuse fault detection, over-voltage protection, and alarms to avoid damage or part defects.

Why Is It Essential?

In a hot-runner system, maintaining stable and correct temperature is critical for consistent melt flow, avoiding cold- or hot-spots, and ensuring good mold fill, minimal defects and optimal gate vestige.

Because injection molding increasingly uses multi-cavity and multi-zone hot-runner systems, the temperature controller must handle multiple circuits with high reliability and accuracy.

Precise temperature control enables shorter cycle times, fewer scrap parts, and better part-to-part consistency.

Key Component Features To Note:

Microprocessor-based control for high accuracy and fast response.

Dual thermocouple compatibility (J or K type) and dual unit display (°C/°F).

Modular architecture with plug-in temperature control cards for each zone.

Multi-zone output and display, output percentage read-out, and phase/zero-cross trigger options for SSR or triac systems.

Diagnostics capabilities: thermocouple break/reverse detection, fuse fault, over-voltage protection.

Soft-start (intelligent ramp-up of heaters) to extend heater/mold lifetime.

LCD interface with alarm buzzer, event logs, and (in higher-end systems) remote monitoring/communication.

Wide temperature range (for example: K type ~ 32–999 ℉, J type ~ 0–600 ℃) — ranges vary by manufacturer and model.

Applications

Hot runner temperature controllers are widely used in various injection molding sectors that require precise thermal management, including:

Automotive parts (dashboards, lenses, connectors)

Medical devices (precision and hygiene-critical components)

Consumer electronics (housings, structural parts)

Packaging industry (caps, containers, closures)

Multi-cavity molds for mass production

Optical and connector components requiring high consistency

Thick-walled or large molded parts with high heat demand

By using an efficient hot-runner temperature controller, manufacturers can reduce setup time, minimize scrap rates, improve molding precision across multiple cavities, and support advanced hot-runner setups.

Key Features

Modern hot-runner temperature controllers typically include the following functions:

LCD display with intuitive operation interface

Built-in buzzer and alarm notifications

Over-voltage protection to prevent module burnout

Thermocouple disconnection and reverse detection

Fuse failure monitoring

Power output percentage display

Dual selectable trigger modes (phase / zero-cross)

Intelligent soft-start to protect heating circuits

Manual mode fallback in case of thermocouple failure

Automatic/manual control switching

PID auto temperature control

Output percentage limit setting

Dual selectable thermocouple types (J & K)

Dual selectable temperature units (°C / °F)

Multiple alarm output configurations (up to 6 outputs)

Typical temperature range: K type ~ 32 – 999 ℉; J type ~ 0 – 600 ℃

The Development History of Hot Runner Temperature Controllers

Early Stage (Mid-20th Century – 1970s)

The first controllers were simple mechanical thermostats or analog heaters with low precision and slow response times.

They were used mainly on early hot-runner systems, which themselves were less reliable.

Analog Control Era (1970s – 1980s)

Use of analog temperature controllers and relay-based switches became common.

Control was limited to single or few zones with minimal accuracy.

Power control often via contactors or SCRs (silicon-controlled rectifiers).

Digital & PID Era (1980s – 1990s)

The introduction of microprocessors enabled digital temperature control, featuring real-time sensing and PID algorithms for enhanced stability.

Multi-zone controllers emerged to support high-cavity molds.

SSRs enabled smoother switching and less electrical noise.

Modular & Integrated Era (1990s – 2000s)

Modular design of controllers (cards for each zone) improved maintenance and scalability.

Systems with 12, 24, or more channels became available.

User interfaces improved (LCDs, keypads).

Integration with mold and machine control systems began.

Smart & Networked Era (2000s – 2010s)

Touch-screen interfaces introduced, data logging begun.

Fieldbus/industrial communication options (Modbus, Profibus, Ethernet) allowed integration into plant automation.

Advanced fault diagnostics (thermocouple break/reverse, fuse detection) and better protection schemes.

Improved energy efficiency via soft-start, output limiting, and optimized heater drive.

High-Efficiency & Industry 4.0 Era (2010s – Present)

Controllers now incorporate remote monitoring, data analytics, and predictive maintenance features.

Tighter temperature control (smaller deviations) for multi-cavity, precision molds.

Integration with smart factory systems: cloud data, real-time alarms, remote access.

Focus on reducing energy consumption, extending heater and mold life, and optimizing process stability.

Conclusion

From simplistic thermostats to advanced multi-zone intelligent networked systems, hot-runner temperature controllers have evolved dramatically over the past decades. They play a key role in improving part quality, reducing waste, increasing manufacturing efficiency, and enabling modern injection-molding techniques.

Looking ahead, trends lean strongly toward adaptive control (machine learning), full connectivity, and predictive maintenance — making temperature controllers a central component of the smart factory.