IntroductionYou grab a bottle of water from the shelf, twist it in your hand, and notice a small tri...

What Is The Difference Between Semi Hot Runner And Full Hot Runner?

In modern injection molding, efficiency and precision are critical. Among the many mold design choices, hot runner and semi-hot runner (micro semi-hot runner) systems represent two distinct philosophies of material management.

The hot runner aims for zero waste and ultimate efficiency, while the semi-hot runner seeks a balance between performance and cost.

Understanding their differences in structure, temperature control, and application can help mold engineers and manufacturers choose the most suitable system for their production needs.

Structural Design: Full Heating vs Hybrid Flow Paths

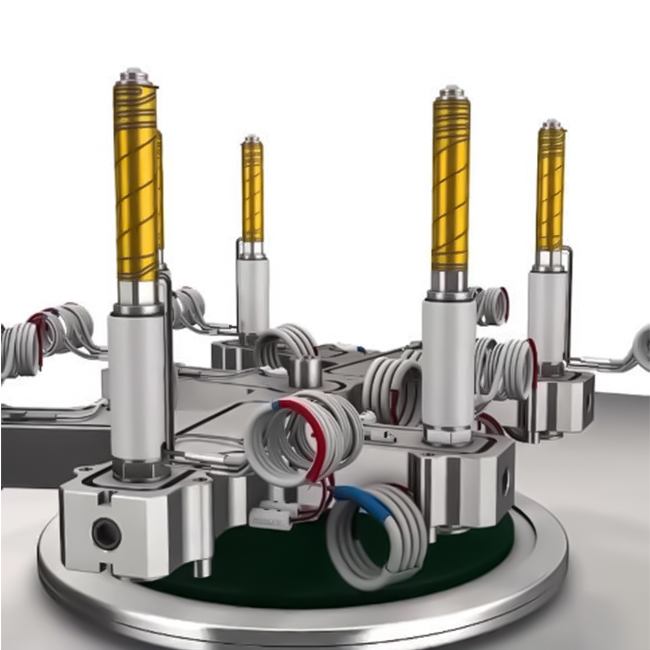

Hot Runner System

The hot runner is a fully heated flow path system. From the injection molding machine nozzle to the mold cavity, molten plastic remains at a high temperature throughout.

Using heated manifolds and hot nozzles (such as valve-gate types), the molten resin flows directly into the part cavity — completely eliminating cold runners and material waste.

The system’s precision depends on stable temperature distribution. Each point must maintain a uniform temperature to prevent localized overheating or solidification.

However, this precision comes with complexity: hot runners require intricate heating components, temperature sensors, and sealing structures that demand expert maintenance.

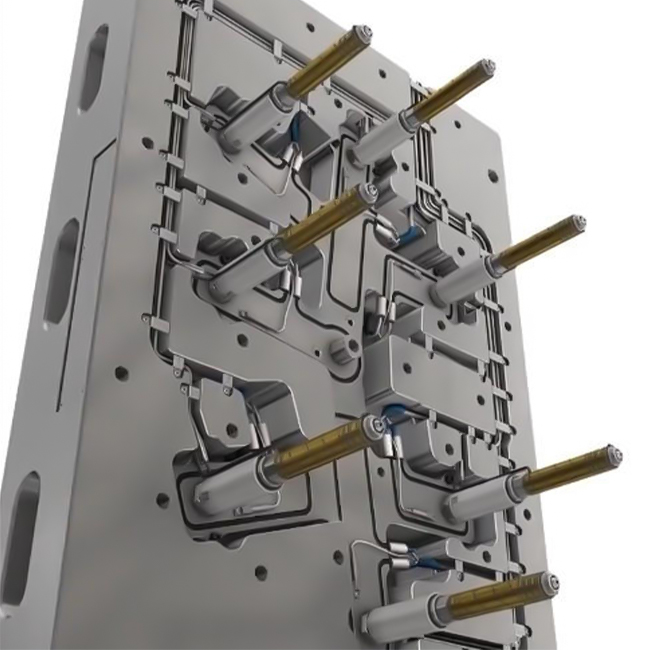

Semi-Hot Runner System

A semi-hot runner (especially the micro semi-hot runner) retains a small portion of cold runner — usually only a few millimeters in diameter — to connect the hot nozzle and the cavity indirectly.

This “hot–cold hybrid” design reduces material waste by more than 70% while simplifying mold construction.

Because it uses an open hot nozzle without complex sealing, the system’s failure rate can be up to 50% lower than a traditional hot runner.

In short:

Hot runner: fully heated, complex, no waste.

Semi-hot runner: partially heated, simpler, minimal waste.

Temperature Control: Active Heating vs Passive Retention

Hot Runner

Hot runners rely on active heating systems with dedicated temperature controllers and thermocouples.

They can achieve temperature accuracy within ±1°C, making them ideal for high-performance materials like PEEK or LCP.

However, precision comes at a cost — one hot runner system typically consumes 2–5 kW, which can add thousands of dollars to annual electricity bills.

Semi-Hot Runner

The semi-hot runner adopts a passive thermal retention approach.

Its open nozzles lack built-in heaters, instead maintaining temperature through residual mold heat and frictional energy generated during injection.

While its temperature stability is lower (±5°C), its reliability is significantly higher.

According to data from an automotive parts manufacturer, a micro semi-hot runner achieved a mean time between failures (MTBF) of 12,000 molding cycles, which is 1.8 times longer than a full hot runner system.

Application Scenarios: Balancing Volume and Flexibility

Hot Runner — Best for Mass Production

Hot runners are ideal for large-scale, high-precision production.

For example, a smartphone casing manufacturer implemented a valve-gate hot runner, reducing its molding cycle time from 35 seconds to 28 seconds and saving over $10,000 in material costs annually.

However, the initial investment is significant — $20,000–$ 50,000 per system — making hot runners suitable mainly for high-volume products (producing millions of parts per year).

Semi-Hot Runner — Perfect for Medium and Small Batches

Semi-hot runners, with their lower setup cost, are better suited for medium-volume or precision parts such as medical components, micro gears, or connectors.

They are also an excellent choice for upgrading existing molds.

In one case study, a connector factory switched to a micro semi-hot runner system, reducing TPE material waste from 15 g to 3 g per shot and cutting flash rate from 8% to 1.5%.

Cost, Maintenance, and Longevity

| Factor | Hot Runner | Semi-Hot Runner |

| Mold Cost | High (complex heating & control system) | 1/3 of hot runner |

| Energy Use | 2–5 kW continuous heating | Minimal (passive heat) |

| Maintenance | Requires skilled technicians | Easier maintenance |

| Reliability | Sensitive to temperature imbalance | More robust |

| Best For | High-volume, high-precision parts | Medium-volume, cost-sensitive projects |

Summary: Efficiency vs Practicality

Both systems have clear advantages:

Hot Runner: Designed for extreme efficiency, precision, and zero waste. Perfect for industries demanding top-tier quality — electronics, automotive, and medical components.

Semi-Hot Runner: Strikes a balance between performance and cost, with simpler maintenance and excellent flexibility for smaller production volumes.

When choosing between them, consider:

Product type and precision requirements

Annual production volume

Budget for mold and energy consumption

Technical capability and maintenance resources

Recommended Product — Smart Temperature Controllers by Cntopower

To maximize the performance of your hot runner system, advanced temperature control is crucial.

CNTOPower Hot Runner Temperature Controllers offer:

±1°C precision temperature management;

Multi-zone control for complex molds;

Energy-saving features that cut power use by up to 20%.

Real-time monitoring and easy operation.

By pairing your hot or semi-hot runner with a reliable temperature controller, you can achieve consistent quality, longer mold life, and lower energy costs.