IntroductionYou grab a bottle of water from the shelf, twist it in your hand, and notice a small tri...

Why More and More Products Use Hot Runner Injection Molding?

Introduction

In modern manufacturing, the demand for efficiency, precision, and sustainability is stronger than ever. Traditional cold runner systems are gradually being replaced by hot runner injection molding technology, which offers significant advantages in energy savings, product quality, and production efficiency.

So why are more and more products — from automotive parts to consumer electronics and medical components — produced with hot runner systems?

Let’s explore the key reasons behind this trend and how this technology continues to evolve.

High Efficiency and Energy Saving

Compared with the conventional cold runner system, hot runner injection molding significantly improves production efficiency and energy utilization.

Since the plastic inside the hot runner system remains molten, the material flow is smoother, which allows for lower injection pressure and temperature during molding.

This improvement brings several advantages:

Reduced energy consumption from heating and injection.

Shorter cycle time, since there’s no need to remelt runners.

Less material waste, as there are no solidified sprues or runners to be discarded or recycled.

In large-scale production, these small differences translate into massive energy savings and higher productivity, making the process both cost-effective and eco-friendly.

Lower Production Cost

Hot runner systems also bring a remarkable reduction in production costs, especially for high-volume manufacturing.

While the initial investment may be higher than for cold runners, the long-term savings far outweigh it.

Here’s how:

No waste from runner material — everything injected goes into the product.

Elimination of secondary processes such as regrinding, recycling, or mixing materials.

Less auxiliary equipment needed, such as cooling towers and mixing devices.

Reduced noise and maintenance costs, since fewer moving and recycling parts are involved.

For manufacturers running thousands or millions of cycles, the return on investment (ROI) of switching to a hot runner system is rapid and substantial.

Ability to Produce High-Quality Products

Hot runner systems are also the key to improving part quality and consistency.

Because the plastic in the manifold and nozzles stays at a controlled temperature, the flow is uniform and stable. This results in:

Fewer defects, such as burns, bubbles, or flow lines.

Better surface finish, ideal for visible components.

Higher dimensional consistency between parts.

Additionally, the temperature uniformity across the system helps manufacturers maintain identical product properties across multi-cavity molds.

For industries like medical devices, automotive interiors, and consumer electronics, this level of quality control is critical.

Lower Injection Pressure Requirement

One of the technical advantages of hot runner molding is its ability to operate under lower injection pressure.

Because molten plastic flows more easily in a heated system, the injection machine doesn’t need to push as hard.

This is especially beneficial when:

Using highly filled plastics (e.g., glass fiber-reinforced materials).

Molding complex geometries or thin-walled parts.

Reducing stress and wear on machines and molds

The result? Extended mold life, less mechanical stress, and more stable processing — all leading to reduced downtime and higher overall efficiency.

Easier Production of Complex Shapes

Another reason behind the growing popularity of hot runner systems is their ability to handle complex product designs.

Cold runner molds often limit designers to simpler geometries due to uneven flow and temperature variations.

Hot runners, however, allow molten plastic to fill intricate mold cavities evenly. This makes it possible to produce:

Multi-cavity precision components

Intricate decorative or functional designs

Thin-wall parts with minimal warping

In industries like toys, electronics, and automotive interiors, where appearance and precision matter, hot runner systems enable designers to achieve their creative and functional goals without compromise.

Development Trends in Hot Runner Technology

As global manufacturing continues to upgrade, hot runner technology is also evolving rapidly.

The following five trends are shaping the future of hot runner systems:

Miniaturization

With the rise of micro injection molding and precision electronics, hot runner systems are becoming smaller and more refined. This allows for accurate control in the production of micro-components and small plastic parts.

Standardization

Manufacturers are moving toward modular and standardized designs, which simplify maintenance, reduce lead times, and make it easier to integrate systems across different mold types.

Improved Reliability

Enhanced sealing technologies, better nozzle materials, and precise machining have led to longer-lasting, more stable systems that can withstand high-temperature, high-pressure environments for extended periods.

Material Improvements

New high-performance alloys and thermal barrier materials are improving system durability and heat transfer efficiency, helping maintain consistent temperature control and reducing energy waste.

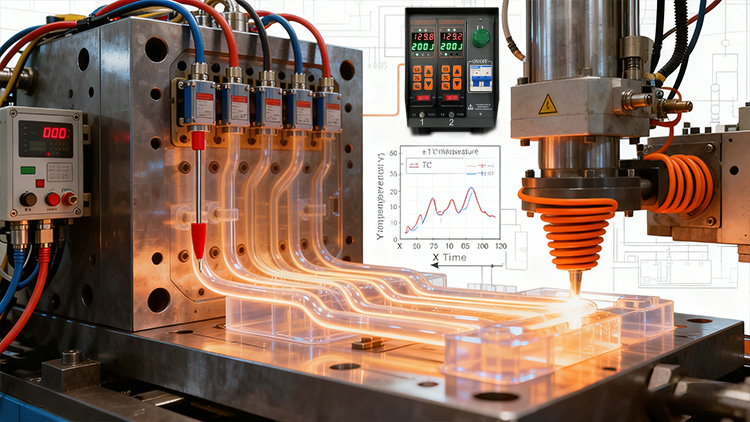

Intelligent Temperature Control Systems

The latest trend is the integration of smart temperature controllers that automatically adjust heat levels based on real-time feedback.

These intelligent systems ensure:

Precise temperature balance in each cavity

Quick fault detection and correction

Overall process optimization and energy efficiency

For example, using advanced hot runner temperature controllers like those from Topower helps manufacturers maintain stable production with less manual adjustment, enhancing both efficiency and product quality.

Conclusion

The increasing adoption of hot runner injection molding is no coincidence — it’s a result of technological advancement and market demand for high efficiency, quality, and sustainability.

From saving energy and reducing costs to enabling complex product designs, hot runner systems have proven their value across various industries.

As trends like miniaturization, standardization, and intelligent temperature control continue to evolve, the technology will become even more accessible and efficient — paving the way for the next generation of smart manufacturing.

Partner with an Expert in Hot Runner Systems

If you’re looking to upgrade your injection molding process with advanced hot runner temperature controllers, visit Topower Hot Runner Temperature Controller.

We offer customized temperature control solutions designed to maximize efficiency, improve product quality, and reduce operating costs.

Contact us today to get a quote or technical consultation for your production line.