IntroductionYou grab a bottle of water from the shelf, twist it in your hand, and notice a small tri...

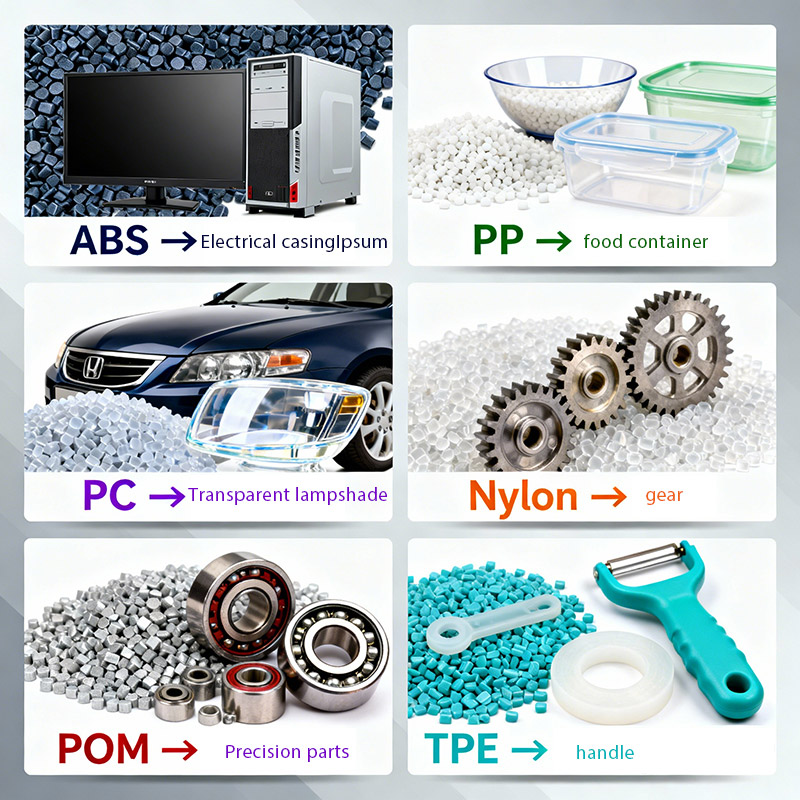

How To Choose The Right Material For Plastic Injection Molding(ABS、PP、PE、PC、PA、PBT)

Choosing the right material for plastic injection molding is one of the most important factors that determine the performance, durability, cost, and manufacturability of your parts. Whether you are developing consumer electronics, automotive connectors, medical devices, industrial components, or household products, selecting the correct injection molding material ensures both production efficiency and long-term reliability.

This guide provides a comprehensive breakdown of the most common polymers used in injection molding, their properties, advantages, limitations, and typical applications. We also offer a practical step-by-step framework to help you decide the best plastic for your project.

Why Material Selection Is Critical in Injection Molding

Injection molding is a high-efficiency mass production process, but the success of each molded part relies heavily on the chosen resin. The right material improves:

Mechanical performance — strength, impact resistance, fatigue life

Thermal stability — ability to withstand temperature without deformation

Chemical resistance — durability against oils, detergents, fuels, and solvents

Dimensional stability — maintaining tight tolerances during long-term use

Surface appearance — gloss, matte finish, transparency, color stability

Production efficiency — cycle time, flowability, shrinkage rate

Cost optimization — material cost + processing cost + mold complexity

This is why proper injection molding material selection is essential for any engineering or manufacturing team.

Mechanical Strength Requirements

Do the parts need to handle load or impact?

Will they bend repeatedly?

Do they require long-term structural stability?

Examples:

high strength: Nylon (PA6 / PA66), PC, PBT

high impact: ABS, PC-ABS, HDPE

flexibility: PP, TPU, TPE

Heat Resistance

Parts exposed to temperature need a polymer with high thermal stability.

120–150°C: Nylon 66, PC, PBT

150–250°C: PPS, PSU

250°C+: PEEK, PEI

Applications include automotive under-hood components, lighting fixtures, and industrial tools.

Heat stability also affects mold temperature, cooling time, and cycle cost.

Chemical Resistance

If parts contact oils, fuels, alcohol, detergents, or cleaning fluids, chemical resistance is essential.

Excellent resistance: PP, HDPE, POM, PTFE, PPS

Moderate: ABS, PC, Nylon

Weak: Acrylic (PMMA)

Chemical compatibility prevents cracking, swelling, or degradation.

Environmental Conditions

Will the part be used outdoors?

Is UV resistance required?

Will humidity or water absorption affect it?

Materials for outdoor use:

ASA → excellent UV resistance

PC → impact resistant + UV-stabilized versions available

PMMA → superior weatherability

For high humidity:

Avoid Nylon unless modified, because it absorbs moisture

Surface Appearance Requirements

If your product is consumer-facing, appearance matters.

High gloss: ABS, PMMA

Matte and textured finishes: PC-ABS, PP

Crystal clear transparency: PMMA, PC

This is crucial in electronics housings, cosmetic packaging, and home appliances.

Regulatory or Safety Requirements

Depending on the application, materials may need additional certification:

FDA / food grade: PP, HDPE, Tritan, medical-grade TPE

UL flame-retardant: FR-ABS, FR-PC, FR-PA

Medical ISO 10993: PC, PP, TPE

Materials must fit compliance standards beyond engineering properties.

Cost and Production Efficiency

Cost consists of:

resin price

molding temperature (energy consumption)

cycle time

scrap rate

mold complexity

Low-cost, easy-to-process materials:

PP, PE, ABS

Higher-cost engineering materials:

PC, Nylon, PBT

Premium high-performance materials:

PEEK, PPS, PSU

Detailed Comparison of Common Injection Molding Materials

Below is an in-depth examination of the most commonly used plastics for injection-molded parts.

ABS (Acrylonitrile Butadiene Styrene)

Key Features

High impact resistance

Easy processing

Good surface finish

Suitable for plating and painting

Applications

Electronics housings

Automotive interior parts

Toys (e.g., LEGO)

Appliance panels

Why choose ABS for injection molding?

It offers an excellent balance of strength, appearance, and cost.

Polypropylene (PP)

Key Features

Lightweight

Chemical resistant

Food-safe grades available

Excellent fatigue resistance (living hinges)

Applications

Food containers

Medical syringes

Hinged caps

Automotive components

PP is one of the most cost-effective and versatile plastics in injection molding.

Polycarbonate (PC)

Key Features

Extremely high impact strength

Transparent

Heat resistant

Good dimensional stability

Applications

Lighting lenses

Safety goggles

Transparent guards

Electronics casings

PC is ideal for protective or transparent components.

Nylon (PA6, PA66)

Key Features

High strength and toughness

Excellent wear resistance

High heat stability

Good chemical resistance

Applications

Gears

Bearings

Automotive engine parts

Industrial components

Nylon is preferred for structural and load-bearing parts.

POM (Polyoxymethylene / Acetal)

Key Features

Low friction

High stiffness

Dimensional stability

Excellent for precision parts

Applications

Gears

Valves

Connectors

Mechanical motion components

Ideal for high-precision components requiring minimal friction.

PMMA (Acrylic)

Key Features

Crystal clear transparency

UV resistant

High aesthetic quality

Applications

Display panels

Automotive lighting

Optical components

PMMA is the best alternative to glass for lightweight optical clarity.

Elastomers (TPE / TPU)

Key Features

Flexible

Soft-touch feel

Durable

Ideal for overmolding

Applications

Tool grips

Wearables

Seals and gaskets

Medical devices

Elastomers enhance ergonomics and sealing performance.

High-Performance Engineering Plastics

Used in extreme environments where standard plastics fail.

PEEK

Withstands 250°C+

Superior mechanical strength

Chemical and radiation resistant

Applications: aerospace, medical implants, oil & gas tools

PPS

Exceptionally heat resistant

Flame retardant

Excellent dimensional stability

Applications: automotive electronics, sensors

PSU / PES

High temperature resilience

Hydrolysis resistant

Applications: food equipment, medical sterilizationThese materials are expensive but irreplaceable in demanding applications.

Step-by-Step Framework for Selecting the Best Injection Molding Material

To simplify decision-making, follow this engineering checklist:

Step 1: Define Mechanical Requirements

Strength? Impact? Flexibility?

→ Choose ABS / PC / Nylon / PP / TPE based on needs.

Step 2: Evaluate Environmental Conditions

Heat? UV? Moisture? Chemicals?

→ PC, ASA, Nylon, PEEK, PP depending on exposure.

Step 3: Determine Aesthetic Expectations

Glossy? Matte? Transparent?

→ ABS, PMMA, PC.

Step 4: Consider Regulatory Compliance

Food-grade? Flame retardant? Medical?

→ PP, HDPE, FR-PC, TPE, medical resins.

Step 5: Balance Material Cost vs. Performance

If cost is critical → PP, ABS

If performance is vital → PC, Nylon

If extreme environments → PEEK, PPS

Material Testing Before Mass Production

Before finalizing your material, consider:

Mold flow analysis (SIMULATION)

Shrinkage and warpage tests

Prototype molding trial

Mechanical performance tests

Chemical compatibility assessments

This ensures the material meets all functional and production requirements.

Conclusion

Selecting the right material for plastic injection molding is a critical engineering decision that affects durability, cost, efficiency, aesthetics, and long-term product success. By understanding key polymer properties and using a systematic evaluation framework, manufacturers can confidently choose the ideal plastic for any application—from cost-effective consumer products to high-performance industrial components.

Improve Your Injection Molding Consistency with Smarter Temperature Control

Material selection matters—but without stable melt temperature, even the best resin can fail.

Our hot runner temperature controllers deliver precise, closed-loop control for ABS, PC, Nylon, PBT, POM, and high-performance polymers, ensuring uniform flow, fewer defects, and shorter startup time.

If you're looking to boost molding efficiency and part performance, let’s connect—we help manufacturers achieve repeatable, high-quality production every day.

Learn more: https://www.cntopower.com/HotRunnerTemperatureController/