IntroductionYou grab a bottle of water from the shelf, twist it in your hand, and notice a small tri...

Open Gate vs. Valve Gate vs. Point Gate: How to Choose the Best Hot Runner Nozzle for Injection Molding

Introduction

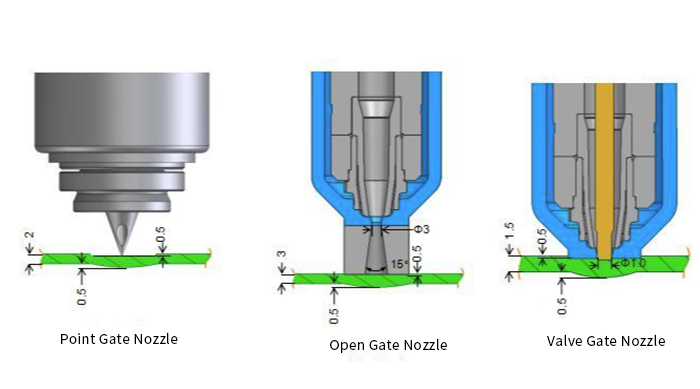

In a hot runner system, the open gate nozzle, valve gate nozzle, and point gate nozzle are the three most widely used injection molding gate types. Their differences lie mainly in gate control, surface appearance, processing stability, and application suitability. Selecting the correct hot runner nozzle has a direct impact on product quality, molding efficiency, cycle time, and mold investment.

This guide provides a complete technical comparison of the three hot runner nozzle types and offers practical selection advice for injection molding engineers and manufacturers.

What Is Open Gate Nozzle?

An open gate nozzle is the simplest type of hot runner nozzle. It delivers melt directly into the cavity through an always-open gate and typically leaves a small cold slug on the product surface. Because it features a large gate diameter, it provides excellent packing pressure, reduces internal stress, and works well for parts that do not require a perfect gate appearance.

How Open Gate Nozzle Works

The melt flows continuously through the open gate during filling and packing. After packing finishes, the gate freezes, forming a cold slug that is later removed manually or via automation.

Open Gate Nozzle Advantages

Large gate diameter ensures strong packing and lower stress

Minimal pressure loss → ideal for high-flow, thick-wall, or large parts

Simple structure and low-cost hot runner nozzle solution

Energy-saving due to reduced shear heat and lower injection pressure

Open Gate Nozzle Disadvantages

Leaves a visible cold slug; unsuitable for high-appearance parts

Requires trimming or removal of the gate residue

Generates more material waste compared to sealed gate systems

Best Applications

Industrial parts, hidden gate locations, non-cosmetic components

Thick-wall parts require strong packing pressure

Cost-sensitive projects and simple multi-cavity molds

What Is Valve Gate Nozzle?

A valve gate nozzle uses a mechanical pin—driven by pneumatic, hydraulic, or electric systems—to open and close the gate. This enables clean, controlled, and repeatable gating, making it the best choice for demanding surface requirements.

Because the valve pin can seal the gate during packing, the process allows shorter cycle times, improved filling balance, and better control of difficult materials.

How Valve Gate Nozzle Works

During injection, the valve pin opens to allow melt flow.

During packing, it remains open until the final packing stage.

Before the resin solidifies, the pin closes the gate to produce a near-gateless appearance.

Valve Gate Nozzle Advantages

No visible gate mark or only a tiny witness ring

Ideal for cosmetic surfaces and high-end applications

Enables sequential valve gating for multi-cavity molds

Reduces shear heat and pressure loss → great for

high-viscosity resins

fiber-filled plastics

heat-sensitive materials

Expands the processing window and improves product consistency

Valve Gate Nozzle Disadvantages

Higher initial investment than other hot runner nozzle types

Requires additional control systems (air, hydraulic, or servo)

Maintenance complexity increases (pin alignment, sealing, and lubrication)

Best Applications

Consumer electronics housings and visible surfaces

Medical devices, automotive interior/exterior components

Multi-cavity molds requiring sequential valve gate control

Thin-wall parts or resins prone to stringing or burning

What Is Point Gate Nozzle?

The point gate nozzle, also known as a tip gate or pinpoint gate, is the most universal hot runner nozzle type. It features a small gate located at the nozzle tip. This gate produces a tiny pinpoint gate mark on the product surface and is suitable for nearly all common plastics.

How Point Gate Nozzle Works?

Molten plastic exits through a small, precisely cooled gate tip. After packing, the gate freezes and breaks off, leaving a small and generally acceptable gate vestige.

Point Gate Nozzle Advantages

Highly versatile and compatible with most thermoplastics

Small and clean gate → better appearance than open gate

Simple structure and moderate cost

Good temperature control around the gate tip

Point Gate Nozzle Disadvantages

Small gate diameter limits packing pressure

Higher shear rate may affect sensitive materials

Not ideal for ultra-high-appearance parts

Best Applications

General-purpose consumer parts

Multi-cavity molds not requiring sequential gating

Cost-sensitive projects needing good aesthetics at lower price

How to Choose the Best Hot Runner Nozzle?

Choosing between an open gate nozzle, valve gate nozzle, and point gate nozzle depends on several engineering and commercial factors.

Selection Checklist

| Criteria | Best Choice |

| Appearance Requirement | Valve Gate Nozzle |

| Cost-sensitive Projects | Open Gate / Point Gate |

| Difficult Materials (GF, PA, PC, etc.) | Valve Gate |

| Hidden Gate / Industrial Parts | Open Gate |

| Multi-Cavity with Balance Issues | Valve Gate (Sequential Control) |

| Short Cycle Time Requirements | Valve Gate |

| General Purpose | Point Gate |

Summary of Each Type

Valve Gate Nozzle → Best performance, perfect gate appearance

Point Gate Nozzle → Balanced performance, widely applicable

Open Gate Nozzle → Most economical, excellent packing

Conclusion

Each hot runner nozzle type—open gate, valve gate, and point gate—offers distinct advantages depending on the product design and production requirements.

If your priority is premium surface quality and advanced process control, the valve gate nozzle is the best choice.

For universal applications at reasonable cost, the point gate nozzle remains the most versatile option.

For thick-wall, large parts, or low-cost production, the open gate nozzle provides excellent process stability and strong packing performance.

By understanding the differences between these hot runner gate designs, injection molding engineers can significantly improve productivity, reduce cycle times, and ensure consistent part quality.