IntroductionIn modern injection molding, precision is fundamental. At the center of that precision l...

Common Challenges in PPO Injection Molding and How to Solve Them

Introduction

Polyphenylene Oxide (PPO) is a high-performance engineering thermoplastic widely used in automotive, electronics, and medical components due to its excellent dimensional stability, heat resistance, and electrical insulating properties. However, like many engineering plastics, PPO presents unique molding challenges that manufacturers must overcome to ensure quality and efficiency. This article examines the most common issues in PPO injection molding and offers practical solutions to help engineers, designers, and manufacturers achieve improved results.

What is PPO

Polyphenylene Oxide (PPO), also known as Polyphenyl Ether, is one of the world’s five major general engineering plastics. It is widely recognized for its high rigidity, excellent heat resistance, flame retardancy, and superior mechanical strength. PPO also offers outstanding electrical insulation, wear resistance, non-toxicity, and resistance to contamination, making it suitable for demanding industrial applications.

One of the most remarkable features of PPO is its low dielectric constant and dielectric loss, which are among the lowest of all engineering plastics. Unlike many polymers, PPO’s dielectric properties are hardly affected by temperature and humidity, ensuring stable performance even under challenging environmental conditions.

Key Properties of PPO

Polyphenylene Oxide (PPO) is a high-performance engineering thermoplastic with a wide range of excellent properties. Below are its major characteristics:

General Characteristics

Non-toxic and lightweight with a relatively low density.

Transparent with excellent dimensional stability.

Outstanding mechanical strength and resistance to stress relaxation and creep.

Excellent water resistance and steam resistance.

Electrical Properties

Exceptional electrical insulation performance.

Dielectric properties are among the best in plastics.

Stable dielectric constant and loss factor, unaffected by temperature or humidity.

Thermal Properties

High heat resistance with a glass transition temperature (Tg) of 211°C.

Melting point of 268°C, decomposition tendency at 330°C.

Heat distortion temperature (HDT) can reach up to 190°C (depending on PPO content).

Load-bearing deformation temperature above 190°C.

Brittle temperature as low as -170°C.

Good flame resistance with self-extinguishing properties; blends with HIPS show moderate flammability.

Chemical and Environmental Resistance

Non-toxic, making it suitable for food and pharmaceutical applications.

Resistant to contamination and most chemicals.

Poor resistance to prolonged UV exposure (may discolor under sunlight).

Blend and Modification Potential

It can be blended or modified with ABS, HDPE, PPS, PA, HIPS, and glass fibers.

Enhances toughness, heat resistance, and processing performance.

Limitations

Poor melt flow properties make injection molding and processing more challenging.

Requires precise processing conditions to achieve defect-free parts.

Applications of PPO Injection Molding

Polyphenylene Oxide (PPO) and Modified PPO (MPPO) are widely used in various industries due to their excellent heat resistance, dimensional stability, electrical insulation, and wear resistance. Below are the main application areas:

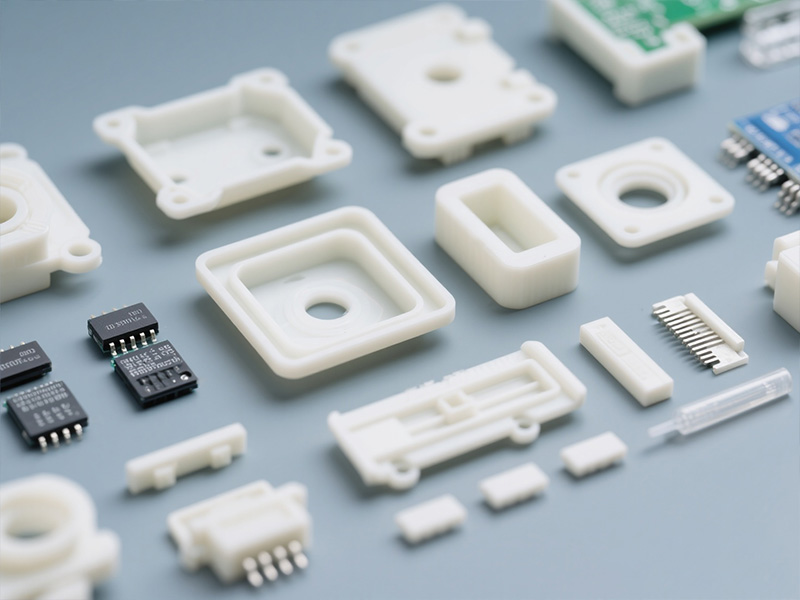

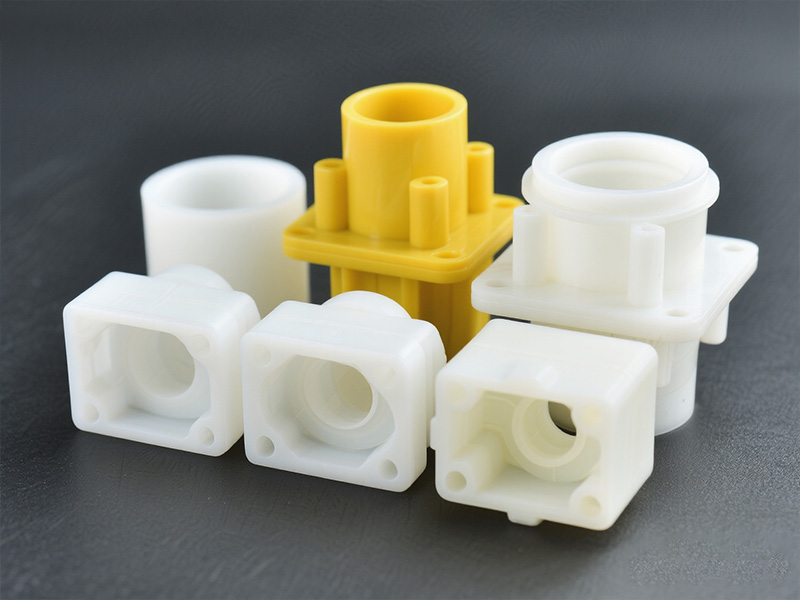

General Components

Heat-resistant parts, insulating components, wear-resistant gears, and transmission elements.

Medical and electronic parts require high precision and safety.

Mechanical and Structural Parts

Gears, impellers, and valves operating at elevated temperatures (can replace stainless steel in certain cases).

Screws, fasteners, and connectors.

Electrical and Electronic Applications

Motor components such as rotors, housings, and transformers.

Electrical housings, connectors, relays, and fuse boxes.

Casings for copiers, computer systems, printers, and fax machines.

Automotive Industry

Instrument panels, radiator grilles, speaker grilles, and control consoles.

Relays, connectors, wheel covers, and under-hood parts.

Large automotive parts via blow molding, including bumpers, flow deflectors, and acoustic panels.

Household Appliances

Components in televisions, video cameras, tape recorders, and audio equipment.

Air conditioners, heaters, rice cookers, and kitchen appliances.

Medical and Industrial Equipment

Camera housings, timers, water pumps, blowers, and silent gears.

Pipes, valve bodies, surgical instruments, sterilizers, and medical device housings.

Large and Complex Products

Large machine housings, bases, and internal support structures.

Common Challenges in PPO Injection Molding and Their Solutions

High Melt Viscosity

Challenge:

PPO has higher melt viscosity compared to standard plastics, which can cause poor flow and incomplete filling in complex mold geometries.

Solution:

Increase mold and melt temperature within recommended ranges (typically 260–300°C).

Optimize injection speed and pressure to improve flow.

Use mold designs with adequate gate sizes and balanced runner systems.

Warping and Shrinkage Issues

Challenge:

PPO has low shrinkage, but uneven cooling or poor mold design can still lead to warpage, affecting part accuracy.

Solution:

Ensure uniform wall thickness to reduce internal stresses.

Use proper cooling channel design to maintain even temperature distribution.

Optimize packing pressure and time to minimize deformation.

Moisture Sensitivity

Challenge:

Although PPO absorbs little moisture compared to other plastics, even small amounts can cause surface defects, voids, or reduced mechanical strength.

Solution:

Pre-dry PPO resin before processing (typically at 100–120°C for 2–4 hours).

Store resin in sealed containers to prevent moisture absorption.

Monitor dew point in drying equipment for consistency.

Burn Marks and Discoloration

Challenge:

PPO is sensitive to overheating, which may cause burn marks, yellowing, or surface defects.

Solution:

Avoid excessive melt temperature.

Ensure proper venting in the mold to release trapped gases.

Reduce injection speed if shear heating is excessive.

Poor Surface Finish

Challenge:

In consumer products and electronic housings, surface quality is critical. PPO may show surface streaks, flow lines, or dull finishes.

Solution:

Use polished mold cavities to improve surface replication.

Adjust injection speed and packing pressure to reduce flow marks.

Optimize mold temperature to achieve a smoother finish.

Weld Line Weakness

Challenge:

When two flow fronts meet, weak weld lines may form, reducing mechanical strength.

Solution:

Increase melt temperature for better flow fusion.

Modify gate locations to minimize weld line formation.

Use gas-assist molding or insert molding to reduce weld line stress points.

Cycle Time Inefficiency

Challenge:

Due to higher processing temperatures, cycle times for PPO injection molding can be longer than for commodity plastics.

Solution:

Optimize mold cooling design with efficient channels.

Use conformal cooling technology or beryllium-copper inserts.

Fine-tune packing and cooling phases to reduce unnecessary delays.

Best Practices for Successful PPO Injection Molding

Material Handling: Always pre-dry PPO resin to prevent moisture-related defects.

Process Monitoring: Maintain consistent melt temperature and injection parameters.

Mold Design: Use balanced runner systems, adequate venting, and cooling channels.

Quality Control: Inspect molded parts for warpage, discoloration, and weld lines early to prevent mass defects.

Industries Benefiting from PPO Injection Molding

Automotive: Under-the-hood components, instrument panels, structural parts.

Electronics: Housings, connectors, and insulation parts.

Medical Devices: Equipment casings, sterilizable parts.

Consumer Goods: High-strength housings for appliances and tools.

Conclusion

PPO injection molding is a powerful manufacturing method for producing high-performance plastic components, but it comes with challenges such as high viscosity, warpage, and sensitivity to processing conditions. By understanding these common issues and applying the right solutions, manufacturers can achieve better part quality, reduce defects, and optimize production efficiency.

Partner with Topower to Optimize PPO Injection Molding

Are you facing challenges in PPO or MPPO injection molding, such as:

Incomplete filling caused by high melt viscosity or complex mold geometry.

Warpage, dimensional instability, or cooling-related issues.

Surface defects or weak weld lines affect part quality.

High-performance demands in heat resistance, electrical insulation, and wear resistance.

At Topower, we provide advanced solutions to help you overcome these challenges and achieve stable, efficient, and high-quality molding results.

Our Products & Solutions

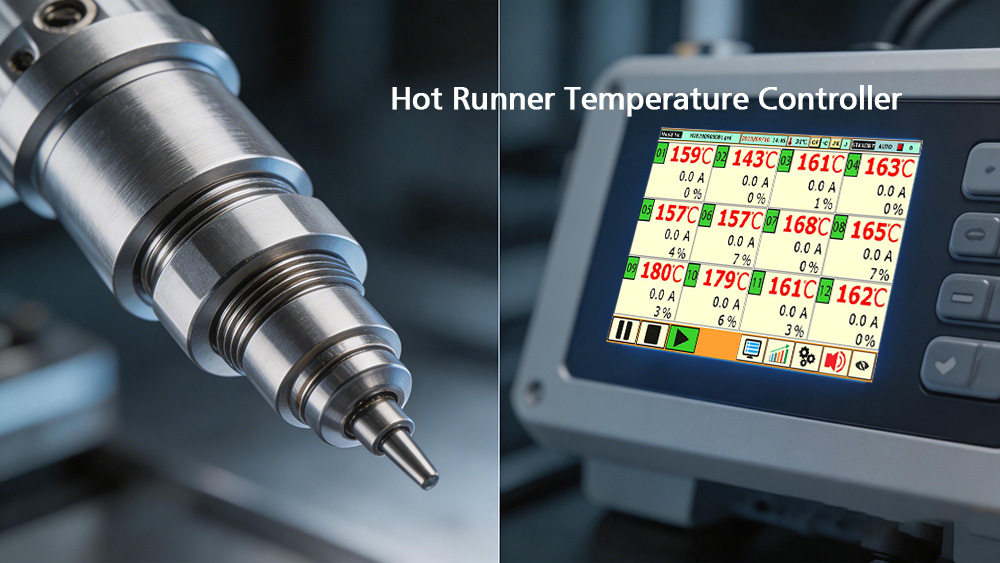

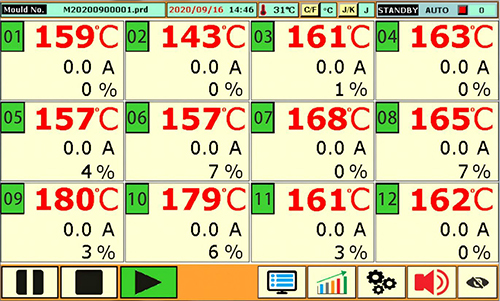

Hot Runner Temperature Controllers: Multi-zone (1–120 zones) controllers designed for precision temperature management. Compatible with leading mold brands (YUDO, DME, HUSKY, etc.), ensuring uniform PPO melt flow and reducing cold spots. → View More

Time Sequential Controllers: Ideal for valve-gate or multi-cavity molds, allowing sequential gating to eliminate weld line weaknesses and optimize flow balance. → View More

Accessories & System Integration: Reliable cables, connectors, and modular components that ensure smooth operation between your injection machine and molds. → View More

Contact Us Today

If you are ready to:

Improve the performance of PPO molding

Reduce defects such as warpage, sink marks, and weak weld lines

Enhance efficiency while saving energy and material costs

Get in touch with Topower Electronic Technology Co., Ltd. today!

Email: sales@topower-controller.com

Phone: +86-13825218815

Website: cntopower.com