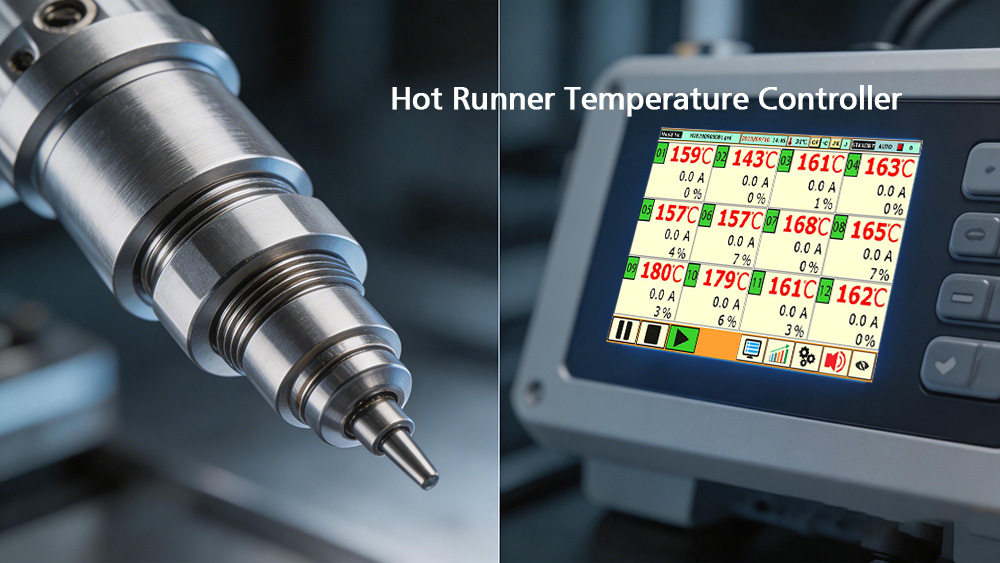

IntroductionIn modern injection molding, precision is fundamental. At the center of that precision l...

10 Key Parameters for Choosing a Hot Runner Temperature Controller

In the injection molding industry, hot runner temperature controller is essential to ensure stable mold performance and consistent product quality. As the demand for precision, appearance, and performance of plastic parts continues to rise, choosing the right temperature controller has become more critical than ever.

This 2025 ultimate guide will walk you through the 10 key parameters to consider when selecting a hot runner temperature controller, helping you make smarter decisions for your production line.

Temperature Control Accuracy

Temperature accuracy is the most critical factor. Different applications require different precision levels. In general, ±0.1℃–±1℃ control accuracy is sufficient for most molding operations.

A common question is: “What temperature controller accuracy is suitable?” If your production requires high gloss surfaces or tight dimensional tolerances, a higher accuracy unit (±0.1℃) is recommended. For general applications, ±1℃ accuracy is usually enough.

Number of Control Zones

With increasingly complex mold designs, hot runner systems require more heating zones. Common options include single-zone and multi-zone temperature controllers.

Large or complex molds: 48 zones or even over 120 zones

When evaluating, always align with your mold’s heating circuits. Many buyers specifically search for “multi-zone temperature controller selection” to ensure scalability.

Thermocouple Type Compatibility

Hot runner controllers typically support J-type and K-type thermocouples. Understanding their differences is key:

J-type thermocouples are better suited for medium-to-low temperature applications, offering stability and reliability.

K-type thermocouples: Wider temperature range, suitable for higher temperature environments.

Before purchasing, confirm which type your mold system uses. Many customers ask about the “difference between J-type and K-type thermocouples” before making a final decision.

Control Algorithm (PID)

Advanced controllers adopt adaptive PID algorithms to ensure rapid and stable heating. Unlike basic on/off control, PID minimizes overshoot and maintains a steady temperature, thereby improving part consistency and surface quality.

Power Supply and Output Power

Check the controller’s power specifications (single-phase/three-phase, 220V/380V) and per-zone output power.

If the power is insufficient → slow heating.

If the power is too high → energy waste and temperature overshoot.

The right balance ensures efficiency and safety.

Alarm and Safety Protection

High-quality controllers must include safety features such as:

Thermocouple break alarms

Heater short-circuit protection

Over-temperature protection

Overload current protection

These safeguards reduce downtime and protect your equipment.

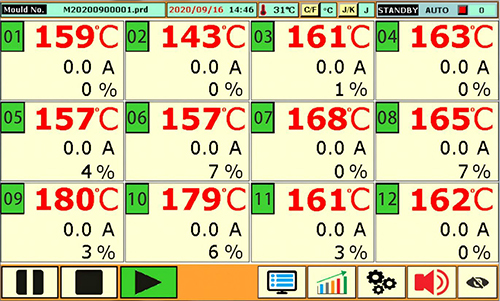

User Interface and Ease of Operation

Modern controllers feature touchscreen interfaces with intuitive navigation. Some models even support remote monitoring, making them ideal for smart factory integration.

If you frequently change molds or process parameters, a controller with data storage and recipe management is a smart investment.

Scalability and Compatibility

Production requirements grow over time. Ensure your temperature controller supports modular expansion and compatibility with different hot runner brands. This extends equipment life and reduces long-term costs.

Cooling and System Stability

Continuous high-power operation generates heat. Efficient cooling systems such as forced-air cooling or optimized heat dissipation, help extend the life of electronic components and keep operations stable.

Brand Reputation and After-Sales Support

Finally, reliability depends not only on hardware but also on after-sales service. Partnering with a trusted manufacturer ensures technical support, training, and fast troubleshooting. Since hot runner controllers are long-term investments, strong after-sales support is critical.

Conclusion: How to Choose the Right Hot Runner Temperature Controller?

When selecting a controller, consider:

Accuracy → based on product tolerance needs

Thermocouple compatibility → J-type or K-type

Number of zones → single-zone or multi-zone based on mold size

Control algorithms, power, and safety → for stable, efficient operations.

By combining these 10 parameters, you can select the most suitable solution for your molding applications.

Why Choose Topower Hot Runner Temperature Controllers?

With over a decade of expertise in hot runner control systems, Topower delivers precision-engineered solutions for injection molding manufacturers worldwide.

Our temperature controllers feature:

±0.1℃ accuracy for high-precision molding Full compatibility with J-type and K-type thermocouples

Multi-zone options ranging from 1 to 120 zones

Modular design for flexible expansion

7-inch touchscreen interface for easy operation

Comprehensive safety protection systems

Whether you serve the automotive, packaging, or electronics industry, CNTOPower offers reliable and efficient hot runner temperature control solutions tailored to your needs.

Visit www.cntopower.com today to get your customized solution and make your molding production smarter, faster, and more stable!