IntroductionYou grab a bottle of water from the shelf, twist it in your hand, and notice a small tri...

Small Run Injection Molding vs. Mass Production: Which Is Right for You?

When planning plastic part production, companies often face a critical decision: small run injection molding or mass production. Each option has unique benefits and trade-offs depending on budget, time-to-market, and long-term demand. For startups testing prototypes, low-volume runs may be the most efficient choice. For established products with predictable demand, large-scale production is often more economical.

This article compares small run injection molding with mass production to help you decide which approach fits your project.

Understanding Small Run Injection Molding

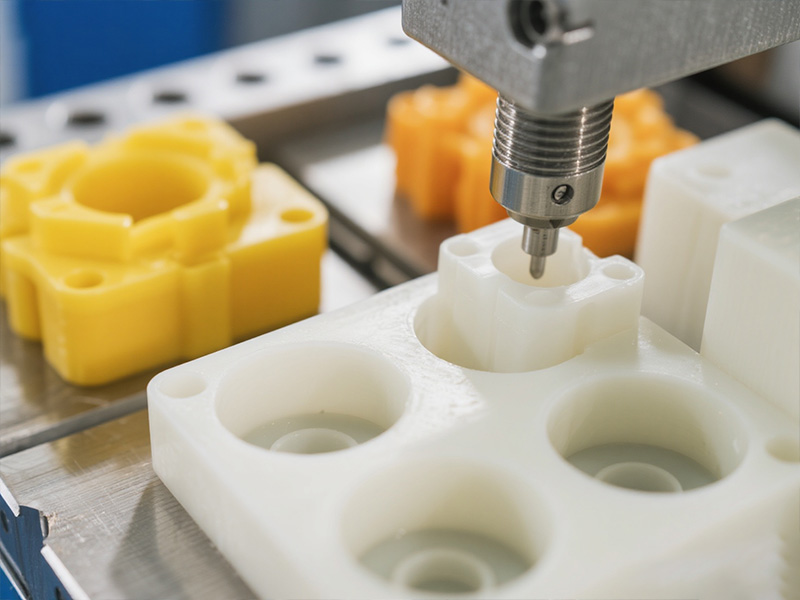

Small run injection molding, also called low-volume or short-run molding, typically involves producing hundreds to several thousand parts. Instead of heavy-duty hardened steel molds, manufacturers may use aluminum or hybrid tools to reduce cost and lead time.

Key benefits include:

Lower upfront tooling cost

Faster turnaround time

Flexibility for design changes

Reduced inventory burden

However, because molds wear out faster, the per-unit cost tends to be higher compared with mass production.

Understanding Mass Production

Mass production injection molding involves creating tens of thousands to millions of identical parts using hardened steel molds built for durability. This approach is ideal for high-demand, long-term products where the high tooling investment can be spread over a large number of units.

Key benefits include:

Lowest per-unit cost at scale

Consistency and repeatability

Long tool life (hundreds of thousands of cycles)

Suitable for global product launches and standardized components

The trade-off is high upfront investment, longer lead times, and less flexibility for design modifications.

Understanding Small-Run vs. Mass Production Injection Molding

Small-run injection molding uses simpler, lower-cost tooling (often aluminum or pre-hardened steel) and is optimized for limited quantities. It’s well-suited for prototypes, pilot production, and niche products. By contrast, mass-production molding uses durable steel molds built for high-volume runs, which have a high upfront cost but very low per-part cost over millions of cycles.

Batch size: Short runs typically range from a few dozen up to ~10,000 parts. Mass runs produce hundreds of thousands to millions of parts.

Tooling: Short-run molds are made quickly from aluminum or soft steel, reducing lead time and cost. Mass-production molds are hardened steel, which lasts longer but takes months to fabricate and costs tens of thousands .

Per-Unit Cost: Because short runs make few parts, the lower tooling cost is offset by a higher cost per piece. In contrast, high-volume runs spread the mold cost over many parts, driving unit cost down dramatically.

Choosing the right mode depends on your production volume, budget, and long-term plans. Short-run molding shines when you need agility – quick starts, design changes, and limited inventory. Mass production is ideal for stable products with very high demand, where the goal is to minimize per-unit cost.

Comparing Small Run Injection Molding vs. Mass Production

| Factor | Small Run Injection Molding | Mass Production Injection Molding |

| Tooling Cost | Low (aluminum or hybrid tools) | High (hardened steel molds) |

| Lead Time | Fast (weeks) | Longer (months) |

| Per-Unit Cost | Higher | Lower at scale |

| Flexibility | High (easy design changes) | Low (expensive to modify) |

| Tool Life | Limited (10k–100k cycles) | Long (hundreds of thousands to millions) |

| Best For | Prototypes, startups, niche markets, bridge production | Established products, stable high demand |

Benefits of Short Run Plastic Molding for Agile Manufacturing

Short-run or low-volume injection molding provides several advantages for fast-paced product development:

Lower upfront investment: Tooling can cost just a few thousand dollars with aluminum molds, versus tens of thousands for steel. This makes short runs affordable for startups or new product trials.

Faster turnaround: Rapid tooling and simpler molds shorten lead times. Small runs can often be set up in days or weeks instead of months, letting you get parts in hand quickly. This is critical for tight deadlines and fast-moving markets.

Design flexibility: With short-run molds, you can iterate on designs cheaply. Making a new aluminum mold for a design change is much easier and less costly than reworking a hardened steel mold. This agility is ideal for prototyping and refining parts before committing to full-scale production.

Customization and small-batch runs: Short runs enable limited-edition or customized products without massive investment. You can produce niche or personalized items (colors, features, variants) because tooling costs and risks are low.

Risk mitigation: Producing a small batch lets you test the market or validate a new design with minimal risk. You gather customer feedback and make improvements before scaling up, avoiding costly mistakes and inventory obsolescence.

In summary, short-run injection molding gives procurement teams agility: lower cost barriers, quick delivery, and the ability to adapt to change. This makes it a powerful tool for R&D, pilot projects, and just-in-time manufacturing.

Flexibility and Customization in Short-Run vs Mass Injection Molding

Design Flexibility: Short-run molding is highly flexible. Tools can be revised or replaced quickly, enabling design tweaks and custom features between runs. This flexibility means you can iterate prototypes or offer custom versions (different colors, branding, minor geometry changes) without huge penalties. For example, small-batch runs can produce limited-edition products or accommodate regional variations on demand.

In contrast, mass production molds are rigid. Once a steel mold is made, making design changes is expensive and time-consuming. Mass runs are best for mature products with established designs. Customization in mass production usually requires completely new molds or complex adjustable tooling, which adds cost and risk. Procurement managers should note that if their product roadmap includes frequent updates or variations, short-run injection molding provides the needed agility.

Production Volume Flexibility: Short-run allows scaling up gradually. You can conduct a pilot batch for market testing, followed by a second batch, and so on, without committing to a million-piece run. This reduces the risk of overproduction. Conversely, mass production is an “all-in” approach – you must forecast demand accurately, since ramping down a mass line is difficult and wasteful.

Supply Chain and Localization: Short-run capabilities often result in local or regional suppliers, as low-volume shops proliferate. This can reduce lead time and simplify logistics for custom parts. Mass production, especially overseas, can introduce long supply chains and less flexibility to pivot if demand shifts.

Overall, short-run molding is ideal when customization and responsiveness matter, whereas mass molding excels in volume consistency.

Quality Control: Ensuring Consistency in Short and Long Runs

Quality control and consistency are paramount in injection molding. Both small and large runs demand precise process control, but the approaches differ:

Mass Production: High-volume runs benefit from stable, automated processes. Hardened steel molds and robust machinery yield very repeatable results once parameters are dialed in. Automated inspection can run continuously, and small variance in one part is amplified over millions, so quality assurance is critical. Long-run molding often leverages statistical process control and heavy automation to maintain uniform quality.

Short-Run: In small batches, you can catch and fix issues early. Since quantities are limited, operators often perform manual inspections on first-off parts and can adjust parameters or rework tools mid-run. This iterative feedback loop often leads to more immediate improvements. Modern digital quality systems (even manual checks) provide real-time monitoring, which can reduce scrap and defects. Short-runs inherently have more scrutiny per part, supporting consistent outcomes.

Hot Runner Systems: Many injection molding processes use hot runner molds, which keep the plastic molten in the runners, eliminating wasted scrap and reducing cycle times. However, hot runners require precise temperature control. Inconsistent nozzle temperatures can cause defects or inconsistent fills.

Hot Runner Temperature Controllers: A specialized hot runner controller maintains uniform heat across all zones. By using thermocouples or RTDs in each nozzle, modern controllers adjust power to heating elements in real time, keeping each cavity at the setpoint. This precision ensures that even complex or thin-walled parts mold correctly. For procurement managers, investing in a reliable multi-zone controller means both short-run and mass runs yield higher quality parts with fewer rejects.

In summary, both methods can achieve high quality, but the strategies differ. Mass production relies on locked-in processes and automation, while short-run molding emphasizes flexibility and immediate feedback. In either case, hot runner technology and advanced temperature controllers play a key role in maintaining tight tolerances and efficient molding.

Conclusion

Ultimately, the choice between short-run (small batch) injection molding and mass production depends on your product lifecycle stage, demand certainty, and business goals. Short-run molding offers flexibility, lower upfront costs, and faster iteration, making it ideal for R&D, market testing, and niche products. Mass production brings efficiency and scale, delivering very low unit costs for proven, high-demand products. Procurement managers should evaluate each project’s volume, budget, and time constraints.

Whichever path you choose, integrating advanced hot runner technology and reliable temperature control is crucial for consistent quality and cost control. For example, CNTOPower’s hot runner temperature controllers exemplify how precise thermal management can support both small-batch agility and mass-production consistency. By weighing these factors – cost, lead time, flexibility, quality, and technology – you can make an informed decision that optimizes your product development and manufacturing strategy.