IntroductionYou grab a bottle of water from the shelf, twist it in your hand, and notice a small tri...

Hot Runner vs Cold Runner: Which Is Best for Your Mold Design?

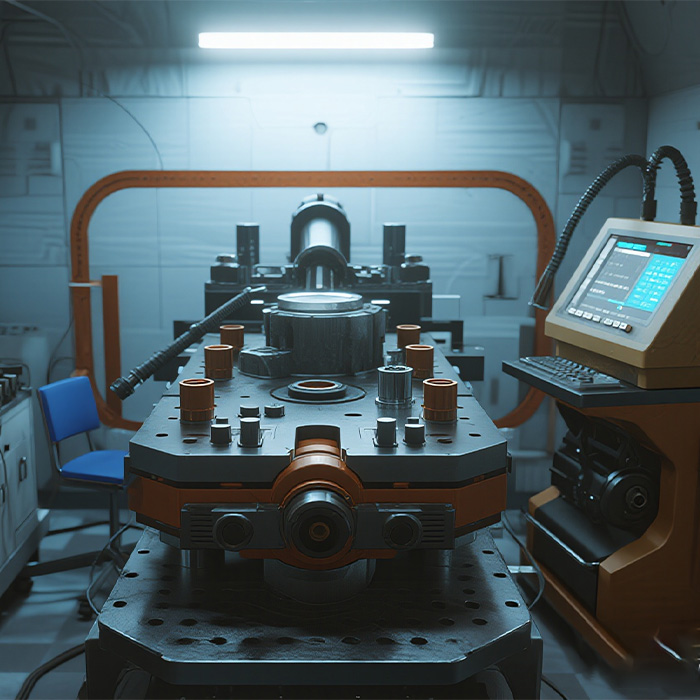

Choosing the right runner system is one of the most important decisions in injection molding. Two popular options dominate the industry: hot runner systems and cold runner systems. Both play a crucial role in how plastic flows into the mold cavities, but their design, cost, and performance differ significantly. So, which is better for your mold design? Let’s find out.

What Is a Runner System in Injection Molding?

In injection molding, a runner system is the pathway that guides molten plastic from the injection molding machine’s nozzle to the mold cavities. This system determines how efficiently material flows and whether the final parts are consistent in quality.

Why Runner Systems Matter for Mold Design

An efficient runner system minimizes waste, ensures uniform filling, and improves cycle times. The right choice between hot runner and cold runner can significantly impact production cost and product quality.

What Is a Hot Runner System?

hot runner system uses heated components to keep the plastic molten inside the runners throughout the molding process. This eliminates solidified waste and improves material efficiency.

How Hot Runner Systems Work

Hot runners use temperature-controlled manifolds and nozzles to maintain the plastic in a molten state until it enters the mold cavity.

Key Advantages of Hot Runner Systems

Less Material Waste: No solidified runners to dispose of.

Faster Cycle Times: Eliminates regrinding and remelting.

Better Part Quality: Improved surface finish and consistency.

What Is a Cold Runner System?

A cold runner system, on the other hand, allows the plastic to solidify in the runners along with the molded parts. These runners must be removed and often reground for reuse.

How Cold Runner Systems Work

Plastic flows through unheated channels and solidifies after each cycle, resulting in runner scrap.

Key Advantages of Cold Runner Systems

Lower Initial Cost: Simpler design and lower mold price.

Easier Maintenance: Fewer temperature control components.

Better for Frequent Color Changes: No material contamination.

Hot Runner vs Cold Runner: Key Differences

Design and Complexity

Hot runners are more complex, requiring precise temperature control and additional components. Cold runners are simpler and easier to maintain.

Material Waste and Efficiency

Hot runners almost eliminate runner waste, while cold runners generate extra material that must be recycled or discarded.

Maintenance and Downtime

Hot runners require skilled maintenance and careful handling. Cold runners are easier to maintain but increase material handling.

Cost Comparison: Which System Is More Affordable?

Cold runner systems have a lower upfront cost, making them attractive for short production runs. Hot runners have a higher initial investment, but they pay off for large-scale production due to savings in material and cycle time.

Performance and Production Speed

Hot runners deliver faster cycle times, reduced scrap, and better part consistency—ideal for high-volume manufacturing. Cold runners are slower and less efficient for large batches.

Applications: When to Choose Hot Runner vs Cold Runner

Choose Hot Runner: Large production runs, high-precision parts, and when minimizing waste is critical.

Choose Cold Runner: Short runs, frequent color changes, and lower upfront investment projects.

Future Trends in Runner Systems

Innovations such as multi-zone temperature control, smart hot runner controllers, and energy-efficient designs are shaping the future of hot runner technology. Cold runners remain relevant for niche applications but are gradually being replaced in high-volume industries.

a) Smart Hot Runner Controllers

Intelligent temperature control systems are becoming standard in advanced molding operations. These smart controllers use sensors and real-time monitoring to maintain consistent temperatures across multiple zones, reducing defects and improving energy efficiency.

b) Multi-Zone Precision Control

Large and complex molds require multi-zone hot runner systems to ensure uniform melt flow. The latest innovations allow for highly precise temperature adjustments for each cavity, resulting in better part quality and less material stress.

c) Energy Efficiency and Sustainability

Manufacturers are prioritizing energy-saving hot runner designs that minimize power consumption without compromising performance. Features like fast heat-up technology and low-maintenance insulation systems contribute to greener, more cost-effective production.

d) Integration with Industry 4.0

Future-ready hot runner systems will integrate with smart factory ecosystems, allowing remote monitoring, predictive maintenance, and data-driven process optimization. This digital connectivity will significantly reduce downtime and improve overall efficiency.

e) Materials and Coatings for Longevity

Innovations in thermal coatings and advanced alloys are improving the durability and lifespan of hot runner components, reducing maintenance needs and operational costs over time.

Bottom Line: These advancements make hot runner systems more efficient, sustainable, and adaptable for complex, high-precision molding applications. Companies that adopt these innovations will stay competitive in an increasingly demanding market.

Conclusion: Which System Fits Your Mold Design?

Both hot and cold runners have their place in injection molding. Your choice depends on production volume, material costs, sustainability goals, and budget.

Ready to Upgrade Your Mold Design with Advanced Hot Runner Solutions?

At Topower, we specialize in precision-engineered hot runner systems and intelligent temperature controllers designed to optimize your injection molding process. Whether you’re looking to reduce material waste, achieve consistent part quality, or increase production efficiency, our solutions are tailored for high-performance manufacturing.

Whether you need 1 zone or 120 zones, all models adapt to your moulding requirements.

Choosing the right runner system is critical—and if hot runner technology fits your project, we’re here to help you implement it successfully. Contact us today to customize your hot runner solution and take your mold design to the next level.