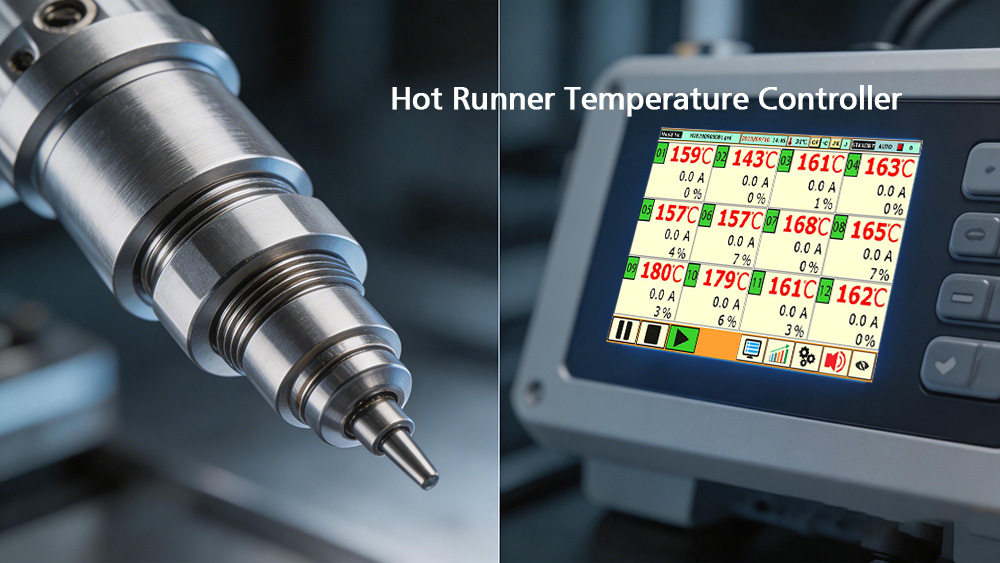

IntroductionIn modern injection molding, precision is fundamental. At the center of that precision l...

Comprehensive Guide: The Role of Temperature Control Switches in Hot Runner Systems

In injection molding, temperature stability is not a luxury—it is a requirement. Even minor temperature fluctuations inside a mold can lead to defects such as short shots, material degradation, stringing, or inconsistent part quality. For manufacturers using hot runner systems, maintaining precise and reliable temperature control is critical to productivity, safety, and cost efficiency.

While much attention is often given to heaters and advanced hot runner temperature controllers, one essential component is frequently overlooked: the temperature control switch. Despite its relatively simple function, the temperature control switch plays a vital role in protecting hot runner systems and ensuring long-term operational stability.

This article provides a comprehensive explanation of how temperature control switches work within a hot runner system, how they differ from temperature controllers, why they matter, and how to select the right solution for industrial injection molding applications.

What Is a Temperature Control Switch?

A temperature control switch is an electromechanical or electronic device designed to open or close an electrical circuit when a preset temperature threshold is reached. Unlike a controller that continuously modulates temperature, a switch operates on a setpoint-based on/off principle.

How It Works

A sensing element (bimetallic strip, capillary sensor, or electronic sensor) detects temperature changes.

When the temperature exceeds or drops below a predefined limit, the switch activates.

The circuit is either interrupted or completed to prevent overheating or underheating.

In injection molding, temperature control switches are most commonly used as safety and protection devices, rather than precision control instruments.

Temperature Control Switch vs. Hot Runner Temperature Controller

Although both devices are involved in temperature management, their roles are fundamentally different.

Feature | Temperature Control Switch | Hot Runner Temperature Controller |

Control method | On / Off | PID continuous control |

Precision | Moderate | High |

Primary function | Safety & protection | Precise temperature regulation |

Response | Threshold-based | Real-time adjustment |

Cost | Lower | Higher |

Why Temperature Control Switches Matter in Hot Runner Systems

Preventing Overheating Damage

Hot runner components such as manifolds, nozzles, and heaters operate at high temperatures for extended periods. If a temperature controller fails, heaters may continue running unchecked, leading to:

Burned heaters

Melt channel deformation

Manifold cracking

Permanent mold damage

A temperature control switch immediately cuts power once a critical temperature is exceeded, preventing catastrophic failure.

Enhancing System Safety

Thermal runaway is one of the most dangerous risks in injection molding. Overheated systems not only damage equipment but can also pose fire hazards and operator safety risks. Temperature control switches provide an independent safety layer that reduces liability and downtime.

Extending Equipment Lifespan

By preventing extreme thermal stress, temperature control switches help extend the service life of:

Hot runner heaters

Wiring and connectors

Insulation materials

Mold steel

This results in lower maintenance costs and more predictable production cycles.

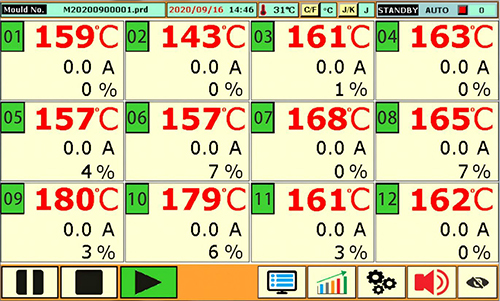

Typical Temperature Control Architecture in a Hot Runner System

A standard hot runner temperature control setup includes:

Heaters – Supply thermal energy to manifolds and nozzles

Thermocouples – Measure real-time temperature

Hot runner temperature controllers – Regulate temperature via PID control

Temperature control switches – Provide over-temperature protection

Installation Locations

Temperature control switches may be installed:

Directly on the manifold

Near nozzle zones

Inside the electrical control cabinet

Integrated into a temperature control module

Their placement depends on the required response speed and protection strategy.

How to Choose the Right Temperature Control Switch for a Hot Runner System

Selecting the correct temperature control switch is critical for reliability. Below are the most important factors to consider.

Temperature Range and Accuracy

The switch must support the operating temperature of your hot runner system, typically between 200°C and 450°C, depending on material and application.

Key considerations:

Maximum allowable temperature

Switching tolerance

Reset type (automatic or manual)

Electrical Ratings

Incorrect electrical ratings are one of the most common causes of premature failure.

Check:

Rated voltage

Rated current

Contact material quality

Environmental Resistance

Injection molding environments are harsh. A reliable temperature control switch should offer:

Resistance to vibration

Protection against oil and plastic fumes

Long-term stability at high temperatures

Compatibility with Temperature Controllers

The switch must integrate seamlessly with your hot runner temperature controller to ensure coordinated shutdown and alarm signaling.

Common Mistakes When Selecting Temperature Control Switches

Choosing Based on Price Alone

Low-cost switches often lack accuracy and durability. Frequent nuisance trips can halt production and reduce overall efficiency.

Ignoring Electrical Load Requirements

Underrated switches suffer from contact burnout, leading to unpredictable failures.

Failing to Match Real Operating Conditions

Different polymers (PP, ABS, PA, PET) require different thermal profiles. The switch must be suitable for actual production conditions—not theoretical values.

Applications Across Injection Molding Industries

Temperature control switches are essential in a wide range of industries using hot runner systems:

Automotive – High-temperature engineering plastics

Medical – Tight process control and safety requirements

Packaging – Continuous high-speed production

Consumer electronics – Precision molding with narrow tolerances

In each case, reliable temperature protection directly impacts product quality and compliance.

The Importance of a Complete Temperature Control Solution

A hot runner system is only as strong as its weakest component. Precision controllers alone cannot guarantee safety without proper protection mechanisms.

Stable temperature control delivers:

Higher part consistency

Reduced scrap rates

Lower energy consumption

Longer mold service life

This is why leading manufacturers invest not only in advanced controllers but also in robust temperature control switches.

CNTOPower: Reliable Temperature Control Solutions for Hot Runner Systems

At CNTOPower, temperature control is not treated as a standalone component—it is designed as a complete, integrated system for industrial injection molding.

CNTOPower provides:

Industrial-grade hot runner temperature controllers

High-reliability temperature control switches

Multi-zone temperature control systems

Customized solutions for complex hot runner applications

Why Manufacturers Choose CNTOPower

Stable and accurate control under continuous operation

Industrial safety standards for high-temperature environments

Flexible configurations for different mold sizes and zone requirements

Proven performance in automotive, packaging, and precision molding industries

CNTOPower temperature control systems are engineered to work seamlessly with hot runner components, ensuring that both precision control and safety protection are fully covered.

Rather than relying on isolated components, CNTOPower focuses on system-level reliability—helping manufacturers reduce downtime, protect molds, and maintain consistent product quality over long production cycles.

Conclusion

Although often overlooked, the temperature control switch is a critical component in any hot runner system. It serves as a silent guardian—protecting equipment, ensuring safety, and preventing costly failures when unexpected conditions arise.

By understanding how temperature control switches function, how they complement hot runner temperature controllers, and how to select the right solution, manufacturers can significantly improve the reliability and lifespan of their injection molding systems.

For companies seeking stable, safe, and scalable temperature control solutions, partnering with an experienced supplier like CNTOPower ensures that every aspect of hot runner temperature management is handled with precision and confidence.

FAQ

What is the main function of a temperature control switch in a hot runner system?

A temperature control switch provides over-temperature protection in a hot runner system by cutting off power when preset temperature limits are exceeded, preventing damage and safety risks.

How is a temperature control switch different from a hot runner temperature controller?

A temperature control switch operates on an on/off basis for safety, while a hot runner temperature controller continuously regulates temperature using PID control for precision molding.

Do hot runner systems need both a temperature controller and a temperature control switch?

Yes. A hot runner system requires a temperature controller for accurate regulation and a temperature control switch as a secondary safety protection device.

What temperature range should a temperature control switch support for injection molding?

Most injection molding hot runner systems require temperature control switches rated between 200°C and 450°C, depending on materials and application conditions.

Can CNTOPower provide customized temperature control solutions for hot runner systems?

Yes. CNTOPower offers customized hot runner temperature control systems, including temperature controllers and temperature control switches tailored to specific molding requirements.

>>Hot runner temperature controller