IntroductionYou grab a bottle of water from the shelf, twist it in your hand, and notice a small tri...

Energy-Saving Strategies for Injection Molding Plants: Can Your Temperature Controller Help?

In today’s manufacturing environment, energy efficiency is no longer optional — it’s essential. For injection molding plants, rising electricity costs and global sustainability goals are pushing manufacturers to find smarter ways to reduce energy consumption without sacrificing production efficiency or product quality.

While motors, heaters, and cooling systems all consume significant amounts of energy, one area is often overlooked: the temperature control system. In fact, optimizing your temperature controller can make a substantial difference in overall energy use.

This article explores how injection molding plants can cut energy costs through temperature control optimization and how advanced solutions like the CNTOPower Hot Runner Temperature Controller can play a vital role in your energy-saving strategy.

Understanding Energy Consumption in Injection Molding

Before improving energy efficiency, it’s essential to understand where the power goes during an injection molding cycle. The main areas include:

Motion and Hydraulic Systems

Hydraulic pumps, servomotors, and drive systems power the movement of the clamping and injection units. Upgrading to servo-driven injection machines or using variable frequency drives can cut energy usage by 20–50%.

Heating Systems

Barrel heaters, hot runners, and mold temperature controllers are the largest contributors to energy consumption. Poorly tuned temperature control systems often waste energy through temperature overshoot, heat loss, or unnecessary standby heating.

Cooling Systems

Chillers, pumps, and water circuits consume considerable electricity, especially if cooling flow is not optimized or runs continuously during downtime.

Auxiliary Systems

Compressed air, lighting, and idle auxiliary machines also contribute to hidden energy costs. Reducing idle time and automating power-down routines can save up to 10% of total plant energy.

Among all these, temperature control represents one of the most accessible and high-impact areas for energy optimization.

How CNTOPower Temperature Controllers Help You Save Energy

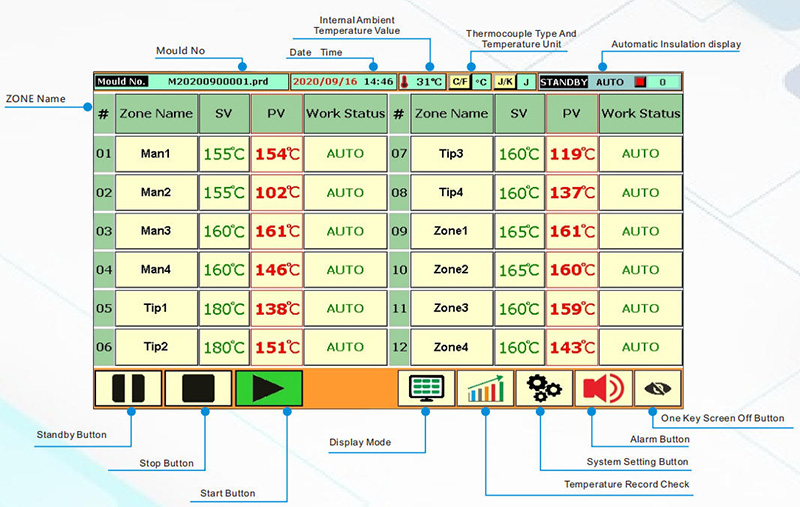

CNTOPower’s Hot Runner Temperature Controller is designed specifically for high-precision, multi-zone injection molding applications. Here’s how it stands out in energy-saving performance:

Multi-Channel Independent Control

Each channel in the CNTOPower controller operates independently, allowing precise tuning of temperature in each hot runner zone. This prevents unnecessary power consumption by keeping only active channels heated.“CNTOPower’s controller automatically identifies idle zones and adjusts them to low-power states — avoiding blanket heating and reducing total system energy demand.”

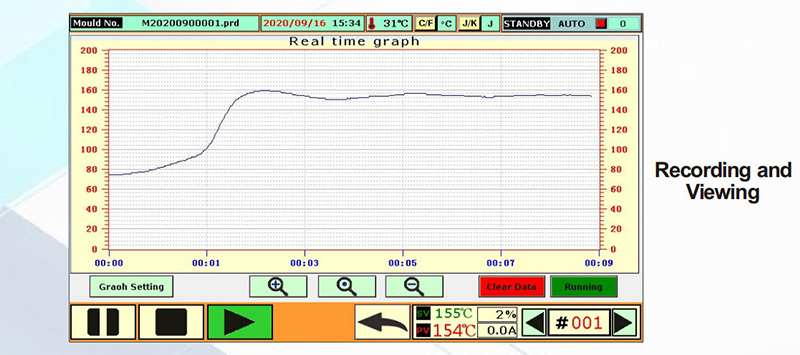

Advanced PID Algorithm and Fast Response

Thanks to advanced PID tuning and rapid response times, the CNTOPower controller stabilizes temperature faster and more accurately, reducing overshoot and heater cycling.

This not only conserves power but also improves part consistency and surface finish.

Smart Power Management

The system features optimized energy distribution logic that adjusts output depending on each zone’s real-time load, ensuring no channel consumes more than necessary.

Robust Design and Thermal Efficiency

Built with high-quality components and thermal-optimized layouts, CNTOPower’s controllers maintain stable performance with minimal heat loss — ensuring both longevity and efficiency.

Integration with Factory Systems

Through interfaces such as RS485, CANbus, Modbus, or Ethernet, CNTOPower controllers can communicate with injection machines and MES systems.

When a machine enters standby or maintenance mode, the controller can automatically lower the temperature or power off unused zones, enhancing system-level energy management.

Practical Energy-Saving Tips for Injection Molders

To achieve maximum efficiency, temperature control optimization should be part of a broader energy management plan. Here are practical steps every injection molding facility can take:

Regular Calibration – Ensure controllers and sensors are calibrated periodically to maintain accurate temperature readings.

Optimize Start-Up Sequences – Use ramp-up heating rather than full-load heating to reduce peak power draw.

Use Insulation Covers – Insulate manifolds, heaters, and pipes to prevent unnecessary heat loss.

Monitor Power Usage – Implement energy meters on temperature controllers to track consumption by each production line.

Combine with Servo Systems – Pair energy-efficient controllers with servo injection machines for maximum power reduction.

Plan Maintenance During Low Demand – Schedule machine maintenance during off-peak hours to reduce unnecessary operation.

Educate Operators – Train staff to use standby modes, adjust setpoints, and recognize overheating conditions.

Why Energy Efficiency Matters More Than Ever

Energy-efficient injection molding is not just about saving money — it’s about sustainability, competitiveness, and equipment longevity.

Efficient temperature control reduces thermal stress on heaters and components, meaning fewer breakdowns, lower maintenance costs, and longer equipment life.

Moreover, many OEM clients today demand greener manufacturing. By investing in intelligent temperature control solutions like CNTOPower’s Hot Runner Temperature Controller, manufacturers can demonstrate a commitment to sustainability while achieving measurable cost savings.

Conclusion: Small Controller, Big Energy Savings

Your temperature controller may seem like a small component, but it has a big impact on your plant’s total energy bill. With the right system in place, injection molding plants can achieve up to 30% or more in total energy savings, reduce carbon emissions, and improve process stability.

If you’re looking to upgrade your energy efficiency, explore CNTOPower’s advanced solutions here:

Hot Runner Temperature Controller – CNTOPower