IntroductionYou grab a bottle of water from the shelf, twist it in your hand, and notice a small tri...

Thin-Wall Molding Challenges: How Precision Thermostats Prevent Warpage

For injection molding and tooling engineers, thin-wall molding—parts with thicknesses under 1.5mm, common in electronics enclosures, medical device components, and automotive miniaturized parts—isn’t just a manufacturing task: it’s a battle against tight tolerances and costly defects. Warpage, in particular, is a top headache: industry data shows it can slash yield rates by 20-35% and add 15% to production cycles when unaddressed. The root cause? Inconsistent temperature control in the hot runner system. Let’s break down why thin-wall molding is prone to warpage, and how precision hot runner thermostats—like those from Topower—solve this critical issue.

Why Warpage Plagues Thin-Wall Molding

Thin-wall parts demand faster fill rates (20-50% higher than standard molding) and narrower process windows. Even tiny temperature deviations can trigger irreversible warpage, and three challenges top engineers’ problem lists:

Melt Temperature Gradients in Narrow Flow Paths

Thin walls mean molten plastic travels through narrow hot runner channels (often 0.5-1mm) over longer distances. Without uniform heat, the melt’s outer layer solidifies faster than the core, creating internal stress that bends the part post-ejection. A 2024 Society of Plastics Engineers (SPE) study found that a mere 3°C temperature variation in the hot runner increases warpage by 40% for PP or ABS thin parts—numbers that hit bottom lines hard.

Multi-Cavity Mold Temperature Imbalances

Most thin-wall production uses 8-32 cavity molds to boost efficiency, but traditional thermostats struggle to maintain consistent heat across all cavities. Hot spots near heaters or cold spots at cavity edges cause uneven shrinkage: one electronics manufacturer reported a 12°C difference between the first and last cavity of their 16-cavity phone charger mold, leading to 30% of parts failing flatness tests.

Material Sensitivity Worsens Defects

Thin-wall applications rely on high-flow materials (PC/ABS blends, PBT, or medical-grade PP) that degrade quickly with temperature swings. Overheating by 5-8°C, and the material’s molecular weight drops, causing uneven crystallization. Underheat, and you’re forced to increase pressure—adding more stress to the part. Either way, warpage follows.

How Precision Thermostats Fix Warpage

The solution lies in thermostats that deliver consistent, real-time temperature control—a hallmark of Topower’s hot runner temperature controllers. Here’s how they address the three core challenges:

±0.1°C Accuracy Eliminates Melt Gradients

Topower’s thermostats (like the TP and TPC series) use platinum RTD sensors and adaptive PID self-tuning algorithms to maintain ±0.1°C precision. Unlike basic thermostats with fixed settings, they adjust heater output in milliseconds: if the melt cools by 0.5°C mid-flow, the controller ramps up heat instantly, preventing premature solidification. A medical molder using Topower’s TP-8 reduced melt variation from 4°C to 0.8°C—cutting syringe plunger warpage by 55%.

Multi-Zone Control Balances Multi-Cavity Molds

Topower’s controllers support 1-32 independent control zones (one per cavity or gate), letting engineers calibrate temperatures for each zone. For example, if cavity 12 runs 2°C cooler (due to proximity to mold coolers), the thermostat boosts its heater output by 3% without affecting other cavities. An automotive parts supplier using a 24-cavity sensor housing mold saw cavity-to-cavity variation drop to <1°C—lifting yield from 68% to 92%.

Fast Response Protects Heat-Sensitive Materials

Topower’s high-power density heaters (15-20W/cm²) and low-latency circuit boards respond in <100ms, keeping melts within the optimal range (e.g., 240-250°C for PC/ABS). This prevents degradation: a packaging molder reported 30% less material breakdown after switching to Topower, eliminating “crystalline spots” that caused bottle cap warpage.

Why Topower Is Your Thin-Wall Molding Partner

For engineers tired of fighting warpage, Topower’s hot runner temperature controllers (https://www.cntopower.com/HotRunnerTemperatureController/) are built to deliver results—no guesswork required:

Proven precision: ±0.1°C control, validated by ISO 9001 and CE certifications, ensures consistent melt temperatures.

Flexible zone options: Choose 1-120 zones to match your mold (from small 1-cavity tools to large 120-cavity production molds).

Smart features: IoT connectivity (via Topower’s monitoring software) lets you track temperatures remotely, set alerts for deviations, and log data for FDA/automotive compliance.

Customization: Topower offers tailor-made solutions for specialized thin-wall applications (e.g., high-temperature resins like PEEK or medical-grade materials).

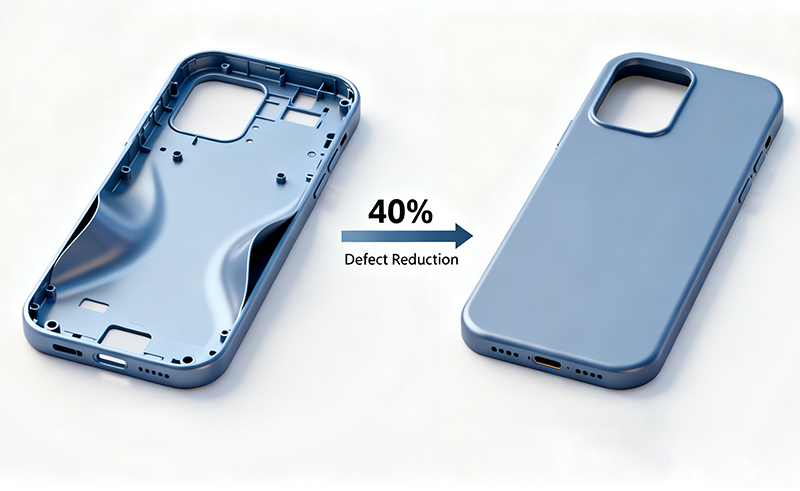

Topower doesn’t just sell controllers—we solve problems. One electronics molder reported a 40% drop in warpage and 20% faster cycle times within 2 weeks of installing Topower’s TPC-16.